Public Utilities

Intelligent Manufacturing

Warehouse Management

Transportation

Energy Industry

Medical Industry

Surveying and Mapping Industry

Mobile Surveying and Construction

Recording limitations Weather Interference Data Inventory Information lag

Outdoor mapping

The accuracy is difficult to meet the requirements due to the influence of the environment, and the recording method is cumbersome and prone to data loss.

Communication base station management

There are many base stations and no unified data management, making it difficult to locate faulty base stations and obtain asset status information for real-time management and inventory.

Ticket management

Conventional ticketing systems lack versatility—manual intervention is needed for gate failures, and fake or duplicate tickets are hard to detect. High passenger volumes during peak seasons further hinder efficient crowd management.

Power inspection

Manual inspections and paper-based records involve many human factors, high costs, difficulty in supervision, low data informatization, and bad weather that can damage files and lead to data loss.

Basic engineering construction

The geographical environment is complex, making route planning challenging. Numerous project plans require confirmation, which is often difficult. Additionally, the acquisition of engineering materials and equipment status is delayed and involves long cycles.

Based on our deep understanding of these industry| problems, we have created a set of targeted solutions based| on the concepts of innovation, efficiency and reliability.

Based on our deep understanding of these industry| problems, we have created a set of targeted solutions based| on the concepts of innovation, efficiency and reliability.

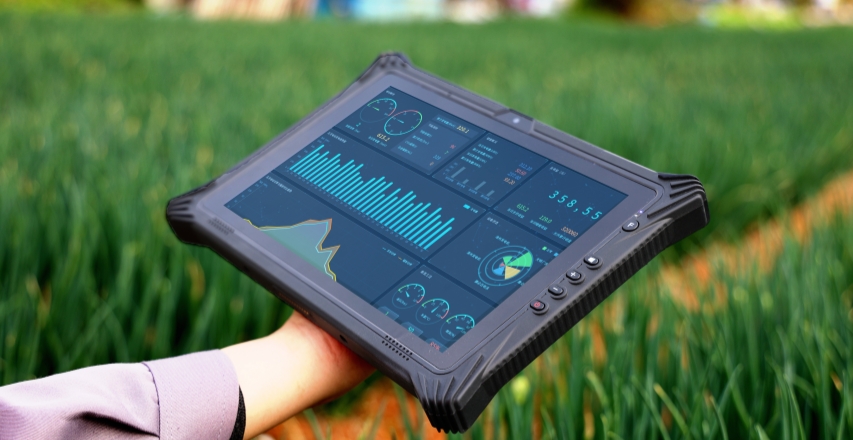

Collect critical data

quickly and accurately

Through stable network transmission function, the collected data is uploaded to the system in real time to ensure the timeliness and integrity of the data, providing strong support for subsequent data analysis and decision-making.

Accurate positioning and navigation Greatly save time and cost

It can determine the specific coordinate information of surveying and mapping points, power equipment, base stations, engineering construction locations, etc. It can also help improve the scientificity and rationality of route planning, provide a basis for project decision-making, and ensure the orderly progress of the project.

Protective performance ensures operation continuity

The high protection level enables the equipment to easily cope with complex and harsh outdoor environments, such as wind and rain, low temperatures, and dusty construction sites. It ensures efficient and continuous operation and reduces the risk of equipment damage and the probability of operation interruption caused by environmental factors.

Provide accurate basis for decision-making management

The deep integration of equipment and information management systems systematizes the heavy management tasks. Through predictive analysis of data, management is strengthened and countermeasures are formulated to reduce the accident rate.