Loading/Unloading Management

Loading/Unloading Management

Emdoor INFO brings barcodes and RFID to all aspects of the logistics industry and quickly realizes the multi-stage digital mode of pickup and delivery, including vehicles, personnel, goods, loading and unloading, and express delivery through rugged handhelds.

Throughout the process, intelligent and transparent management can collect real-time data of each link's time, location, and operator and submit it to the back-end of the platform.

As a result, the rugged handheld significantly improves efficiency, reduces costs, and improves user satisfaction.

Challenge

Due to the different shapes and sizes of express parcels, the staff cannot quickly and effectively evaluate the number of vehicles required to load the parcels each time through skimming, resulting in frequent cases that the parcels are not delivered on time as agreed.

When unloading, it is necessary to manually check the packages one by one, which is very time-consuming and prone to human error. Problems and abnormal packages cannot be dealt with in time, and packages that have been unloaded need to be manually re-entered into the logistics system.

Solution

Use the rugged handheld EM-T60 to scan each loaded cargo. The system will automatically complete the accumulation of the volume and weight data of the loaded cargo, and at the same time, conduct a pre-assessment and complete inspection of each loaded cargo.

If a ticket is too large or overweight to meet the current loading demand, or some cargo fails to reach the car in time, the handheld terminal will automatically send a sign and prompt the reasons for the abnormality so that the loading personnel can take immediate measures.

When unloading, the staff scans and checks the package's barcode through the EM-T60, and transmits the data to the express backstage system through the real-time network. The system will give an alert response to the abnormal package for the first time, which helps avoid disputes at the beginning.

Application

1. The handheld terminal EM-T60 systematically and scientifically evaluate the loaded parcels and give early warning of exceeding the standard parcels, which effectively guarantees the timeliness of the parcels.

2. The accuracy of EM-T60's GPS function can effectively trace the location of vehicles, personnel, and packages.

3. Check the package by scanning the barcode of the goods, and transmit the data to the background in real-time for statistics, avoiding the data error caused by the second manual entry and human error.

4. Fast processing efficiency of abnormal parts can improve management efficiency and customer satisfaction.

Based on our deep understanding of these industry| problems, we have created a set of targeted solutions based| on the concepts of innovation, efficiency and reliability.

Based on our deep understanding of these industry| problems, we have created a set of targeted solutions based| on the concepts of innovation, efficiency and reliability.

Emdoor Information is a trusted leader in rugged mobile computing, with over 20 years of experience delivering innovative solutions for logistics and warehousing. Here’s why Emdoor is the ideal partner for optimizing loading and unloading management:

Conclusion

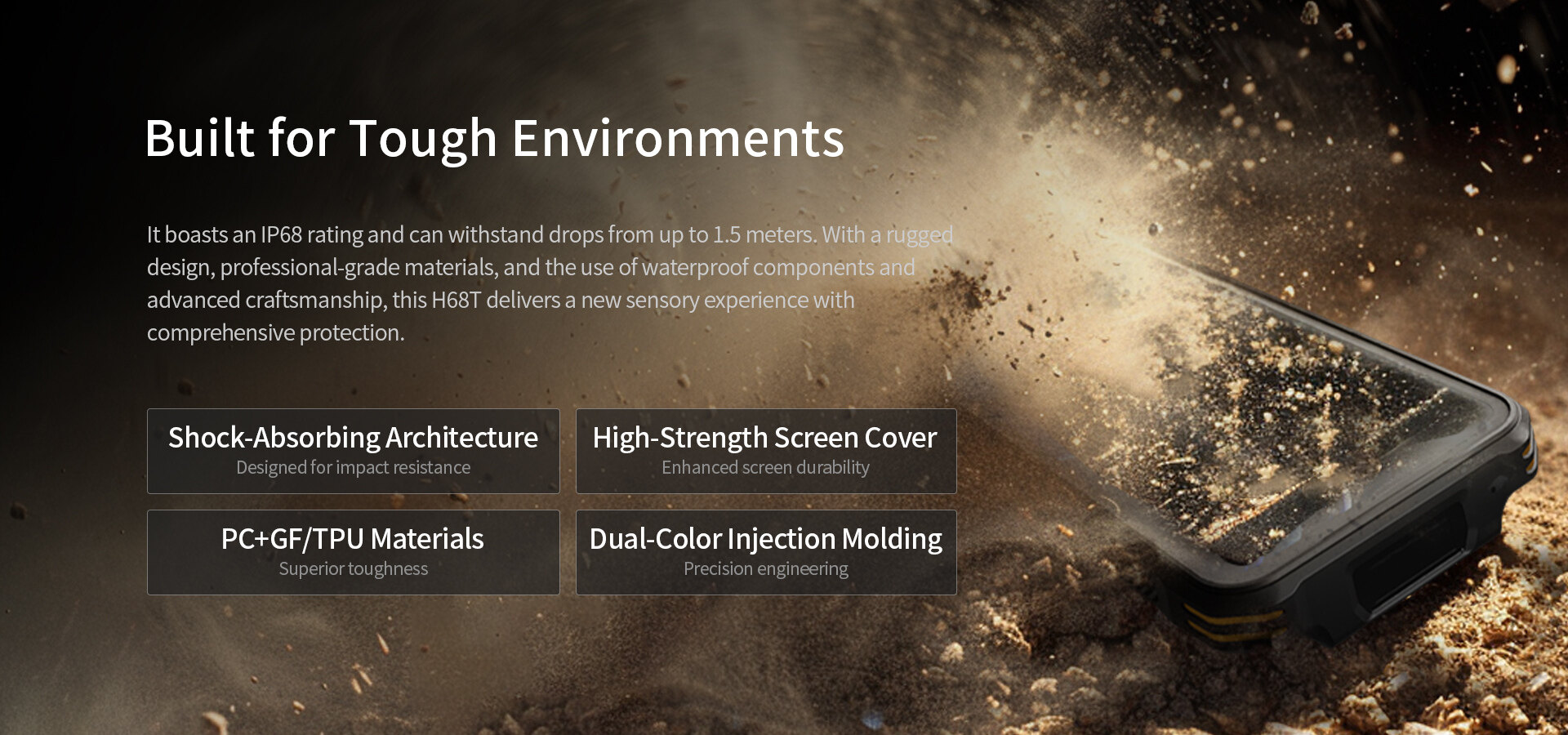

Efficient loading and unloading management is essential for modern warehousing, yet traditional manual processes lead to inefficiencies, errors, and delays. Emdoor Information’s EM-T60 rugged handheld terminal transforms these processes by automating barcode scanning, enabling real-time data synchronization, and providing precise GPS tracking. With applications ranging from optimized vehicle allocation to rapid issue resolution, Emdoor’s solutions empower warehouses to improve productivity, reduce costs, and enhance customer satisfaction.

By addressing the pain points of manual loading and unloading and delivering measurable benefits, Emdoor’s rugged handhelds are a game-changer for logistics operations. To learn more about how the EM-T60 can optimize your warehouse’s loading and unloading processes, visit Emdoor Information’s official website or contact their team for a personalized consultation.