Outbound Management of Warehouse Industry

Welcome back to our comprehensive seven-part series on revolutionizing warehouse and logistics management. In our first article, we provided a broad overview of the challenges and opportunities within the modern supply chain. Now, we begin our deep dive into the specific processes that define operational success. This week, we focus on arguably the most critical, customer-facing stage of them all: Outbound Management.

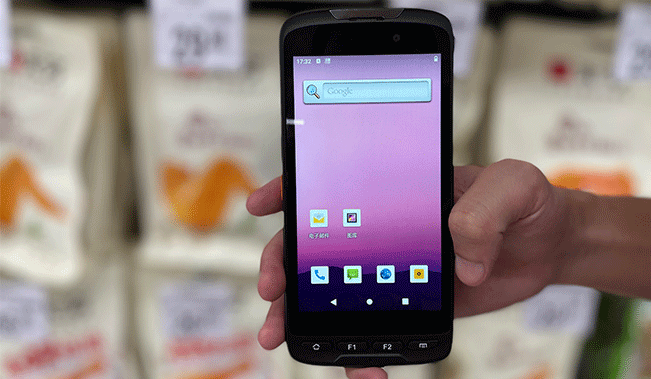

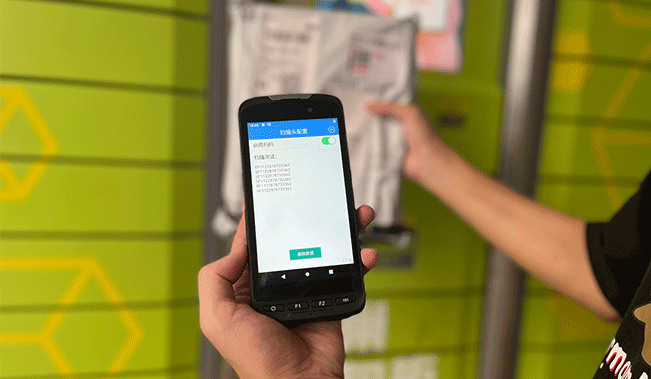

This article delves into the challenges of traditional outbound management and explores how Emdoor INFO's rugged handheld terminals, such as the EM-T50, can usher in a new era of digital, transparent, and efficient warehouse operations through barcode recognition and real-time data synchronization.

Outbound Management

With the increasing market competition, it is of utmost importance for enterprises to improve production efficiency and reduce operating costs. Warehousing and logistics management are now widely used in various industries.

However, due to the low level of industry informatization and facility automation, inventory management is chaotic, express package information is scattered, and low efficiency often occurs.

Designing and establishing a complete set of warehouse management processes, improving warehouse turnover rate, reducing the occupation of operating funds, and reducing the cost caused by eliminating warehousing are the important parts of improving production efficiency for enterprises.

Challange of Outbound Management

In traditional outbound management, the warehouse outbound operations are finished by workers, which has a large workload, time-consuming, low efficiency, and high error rate.

After the delivery is completed, the staff needs to secondly transcribe the records on the paper to the back-end system, which completely relies on manual data update methods.

Often due to various uncertain factors, the inventory and accounts cannot be synchronized, and the efficiency of distribution and delivery is low. Finally, the managers are unable to grasp the real usage of the warehouse in time and formulate a reasonable warehousing plan.

Solution to Outbound Management

Enterprises seeking to modernize their warehouse operations can turn to advanced tools like Emdoor INFO's rugged handheld terminal. These devices replace cumbersome manual processes with automated, intelligent solutions that enhance accuracy and efficiency. Here’s how they work:

Transforming Outbound Operations

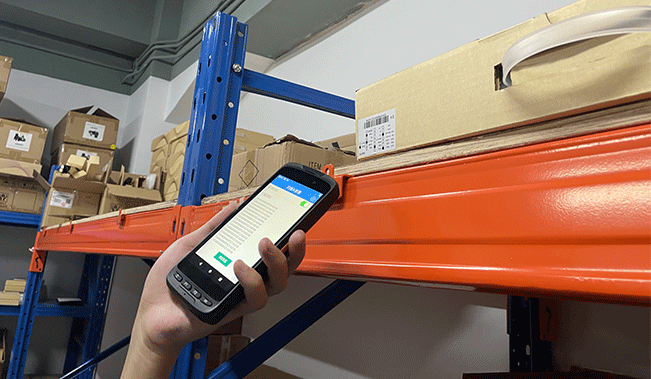

Real-Time Data Access: The EM-T50 connects seamlessly to wireless networks, enabling operators to receive outbound orders instantly. This eliminates delays caused by manual order retrieval.

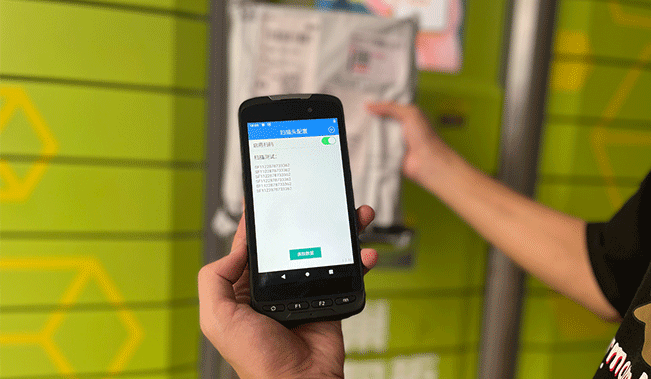

Barcode Recognition: Using its advanced scanning capabilities, the device identifies and verifies products automatically, reducing reliance on human judgment and minimizing errors.

Instant Data Synchronization: Scanned data is uploaded to the central database in real-time, ensuring inventory records remain accurate and up-to-date without manual intervention.

Error Prevention: The terminal’s intelligent verification system flags discrepancies—such as incorrect items or quantities—before they become costly mistakes.

By automating key aspects of outbound management, rugged handheld terminals streamline workflows, reduce labor demands, and provide managers with the real-time insights needed to optimize operations.

Application of EM-T50

The EM-T50 isn’t just a tool—it’s a game-changer for warehouse outbound processes. Designed to thrive in rugged environments, it combines durability with cutting-edge functionality to address the specific pain points of traditional methods.

1. The rugged handheld terminal EM-T50 can receive the outbound information in real-time by the wireless network, and automatically check and record the outbound products, without manual copying and comparison, to avoid errors such as multiple outbound and leaked outbound errors caused by human error

2. The location information is transmitted to the database system in time to ensure that the system accounts are always synchronized with the physical objects.

3. Accurate and real-time inventory dynamics, efficient storage and retrieval efficiency, and accurate and error-free account checking. It has further realized the optimal configuration and management of warehousing goods.

4. The rugged handheld EM-T50 is equipped with an imported scanning head, which can quickly and accurately identify and read barcodes, QR codes, curl codes, pollution codes, fuzzy barcodes, etc. The efficient product identification capabilities greatly improve the work efficiency of operators.

Based on our deep understanding of these industry| problems, we have created a set of targeted solutions based| on the concepts of innovation, efficiency and reliability.

Based on our deep understanding of these industry| problems, we have created a set of targeted solutions based| on the concepts of innovation, efficiency and reliability.

Why Rugged Handheld Terminals Are the Future

The warehouse industry is at a turning point. As e-commerce continues to grow and customer expectations soar, businesses must adapt to stay competitive. Rugged handheld terminals like the EM-T50 offer a scalable, cost-effective solution to modernize outbound management. Here’s why they’re indispensable:

- Accuracy: Automated verification and real-time updates eliminate errors and ensure reliable inventory data.

- Efficiency: Faster scanning and reduced manual tasks accelerate workflows, allowing warehouses to handle higher volumes with ease.

- Cost Savings: Fewer mistakes, optimized resource use, and lower labor costs drive significant financial benefits.

- Scalability: The technology adapts to warehouses of all sizes, from small facilities to sprawling distribution centers.

- To explore how the EM-T50 can transform your operations, check out Emdoor rugged official product page.