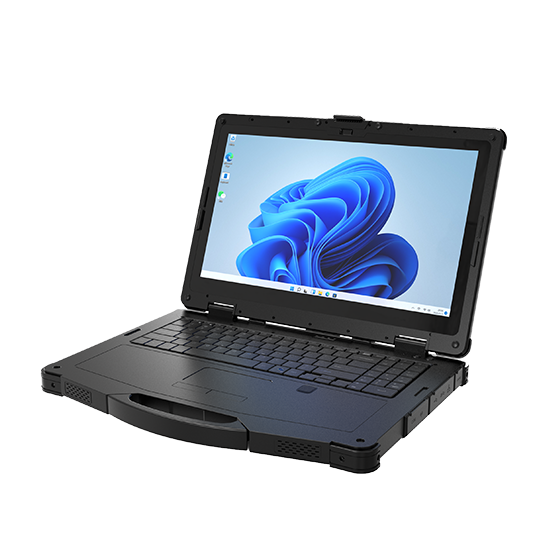

EM-X14U Rugged Notebook Optimizes Railway Maintenance Operations

Challenges

-

In recent years, China's rapid economic development has been accompanied by an increase in railway mileage and the increase in locomotive operation speed. To ensure the normal operation of railways and the safety of passengers, better monitoring, daily maintenance and inspections are required. Relying on manual inspection of railway subgrades, rails, turnouts, signal lights, railway bridges and other basic road conditions on thousands of kilometres of tracks and inspection of facilities along the railway and communication lines are a great challenge for workers in charge of daily maintenance. Moreover, delayed information sharing is not conducive to the timely elimination of railway safety hazards.

Solution

EM-X14U rugged notebook provided by Emdoor, a rugged tablet OEM, integrates data collection, data sharing, real-time communication, and real-time monitoring functions in one. It can assist railway staff to quickly collect equipment operating status and data, share the latest equipment inspection information in real-time, and formulate reasonable inspection routes. And can quickly respond to faults to ensure the normal operation of the railway.

Benefits

EM-X14U rugged computers are improving safety and efficiency for railway administrations in a certain region of China. Its maintenance staff use EM-X14U laptops for daily work to minimize unnecessary downtime, ensure worker safety and maintain open communication lines with managers. Inspectors no longer have to worry about equipment being bumped or rained, because X14U is reliable enough.

Challenges

- The safety and stability of railway transportation are of great strategic significance to the development of the national economy and society. In order to maintain the safe operation of the railway, it is necessary to rely on inspectors for regular inspection and maintenance. However, with the rapid development of railway transportation and the increasing complexity of railway networks, the manual inspection and recording methods adopted by the railway bureau can no longer adapt to today's increasing workload.

- The daily inspection workload is huge, maintenance personnel need to be able to obtain the latest inspection data and reasonable inspection route in real-time to reduce unnecessary waste of time. And need to maintain timely information sharing with other maintenance personnel to achieve efficient communication. However, the railway bureau's method of relying on workers to manually record inspection data on a regular basis and entering the system for statistics after the fact is not only inefficient but also easy to cause inspection data loss or data recording errors. Railway managers are unable to grasp the duty status and walking routes of the inspectors in real-time. In case of emergencies, they cannot get in touch with the inspectors as soon as possible, resulting in restrictions on timely and reasonable personnel dispatching and command.

- On the other hand, patrol inspectors cannot request remote support when facing failures that cannot be decided, resulting in problems that cannot be resolved in time. In order to solve the above problems, the railway administration needs to adopt a ruggedized notebook that can adapt to the harsh environment combined with the inspection management system to intelligently improve the railway inspection process. The EM-X14U is light and powerful. As a device for recording data, querying information, and real-time communication with the background, it can assist field personnel to efficiently and safely complete railway inspections.

Solution

- The X14U rugged notebooks apply mature technologies such as video recording, remote wireless transmission, global positioning, and Internet of Things to the railway inspection system to realize on-site data recording, networking, sharing and other functions, which easily solves the railway bureau's problems.

- In daily work, dispatchers create inspection tasks and send them to designated staff's terminals through the system. Maintenance personnel use EM-X14U to download inspection tasks online and arrive at designated locations to perform tasks according to the inspection routes provided by the equipment. The manager can confirm the position dynamics and movement trajectory of the staff according to the GPS position reported by the X14U in real-time, and check the inspection status through the network to prevent accidents and ensure the safe and stable operation of the railway.

- During the inspection process, maintenance personnel use the industrial notebook's numeric keyboard instead of paper and pen to accurately record the operating status and data of the equipment, simplifying the previous manual transcription and secondary transcription processes, saving time and money. When an abnormal problem occurs, the EM-X14U high-quality front camera and high-speed mobile network allow inspectors to communicate with the background in real-time via video, which is convenient for the dispatch station to mobilize nearby personnel to support or remotely guide the site according to the on-site situation The staff handles it to ensure smoother overall operations.

- The ruggedized computer adds reliability, convenience, speed and improved communication to railway operations. It is compact and portable and can be taken to any place where work needs to be done. The stable network connection allows railway technicians to communicate in real-time while on the move. A powerful hot-swappable battery allows it to run for a full 8 to 9 hours on a single charge. The design of the battery can be replaced at any time to minimize unnecessary downtime, which makes the track inspection work more efficient.