Empowering On-Road Intelligence: How Emdoor Rugged Tablets Solve Core Transportation Fleet Industry Challenges

The Harsh Reality of Transportation: Mobile Devices are Not Optional Anymore

Imagine this: your hundreds of trucks are traversing the country, each a mobile data hub requiring real-time navigation, Electronic Logging Device (ELD) recording, task execution, communication with dispatch, and even vehicle diagnostics. Yet, your drivers are complaining about tablet freezes, unstable signals, or, worse, devices falling from flimsy mounts, causing critical data loss and forced vehicle downtime.

This isn't an exaggeration; it's a common, costly reality for businesses using inappropriate devices in the transportation industry. For fleet managers and purchasers, every mobile device deployed in a truck carries immense responsibility: it must perform reliably under extreme conditions, or it directly impacts regulatory compliance, operational efficiency, driver safety, and ultimately, your company's profitability.

Traditional consumer tablets, even with bulky protective cases, cannot withstand the myriad challenges of a truck cab: continuous vibration, extreme temperature fluctuations, dust, liquids, and glare. Their frequent failures are more than just hardware damage; they lead to a cascading effect of fines, shipping delays, fuel waste, and driver dissatisfaction, culminating in a Total Cost of Ownership (TCO) that far exceeds the initial device cost.

As Emdoor, a leading manufacturer specializing in rugged tablets, we deeply understand the unique demands of the transportation industry. We don't just provide hardware; we deliver well-thought-out solutions engineered to fundamentally address every industry challenge you face.

Now, let's dissect the seven most critical industry challenges that transportation purchasers are concerned about, and demonstrate how Emdoor, with its professional manufacturing capabilities, brings peace of mind and efficient "on-road intelligence" to your operations.

Industry Challenge #1: Lack of Professional In-Vehicle Integration, Leading to Safety & Compliance Risks

The Problem: Consumer tablets lack dedicated in-vehicle mounting solutions. Drivers often rely on flimsy suction cup mounts or makeshift setups, which are highly unsafe during transit. Frequent power cord disconnections due to bumps lead to device shutdowns, interrupting ELD (Electronic Logging Device) records and directly violating regulations. Furthermore, without standardized charging and data ports, cab wiring becomes cluttered, increasing operational complexity.

Emdoor Solution: Professional Vehicle Docks with Secure Locking Mounts

Emdoor deeply understands the unique nature of the in-vehicle environment. Our rugged tablets are designed from the ground up for seamless vehicle integration and are supported by a range of professional-grade Vehicle Docks.

How this solves the challenge:

Military-Grade Secure Mounting: Our vehicle docks utilize VESA standards for robust installation on a truck's dashboard or console. A locking mechanism ensures the tablet remains securely in place even during the most severe bumps, significantly enhancing driver safety by preventing accidental projectile hazards.

Stable, Continuous Power: The vehicle dock provides a stable, wide-voltage power input, designed to handle voltage fluctuations during vehicle ignition and operation. This guarantees the tablet receives consistent power, preventing ELD recording interruptions and ensuring compliance.

All-in-One Connectivity: Drivers simply "click" the tablet into the dock, and all connections (power, external antennas, peripheral ports) are instantly established. Upon exiting, a quick release allows the driver to take the tablet, offering efficient, convenient operation and eliminating messy cab wiring.

Industry Challenge #2: Devices Incapable of Withstanding Constant Vibration and Extreme Temperatures

The Problem: During long-haul transportation, factors like engine vibration and uneven road surfaces create continuous, high-frequency vibrations. Inside the truck cab, summer temperatures can soar above 70°C (158°F), while winter in cold regions can plunge below -30°C (-22°F). Consumer tablets' fragile internal structures and narrow operating temperature ranges quickly succumb to these conditions, leading to chronic damage like solder joint failures, battery swelling/failure, screen blackouts, or inability to power on.

Emdoor Solution: Military-Grade Anti-Vibration and Ultra-Wide Temperature Design

Emdoor's rugged tablets prioritize anti-vibration and wide-temperature capabilities as core design elements. Our products are rigorously certified to the stringent MIL-STD-810H military standard, specifically for sustained vehicle vibration testing.

How this solves the challenge:

Internal Structure Reinforcement: We employ reinforced internal frames, shock-absorbing encapsulation for critical components, and specialized welding processes to ensure our tablets withstand years of continuous vibration without internal structural damage or component loosening.

Ultra-Wide Operating Temperature Range: Emdoor devices support an ultra-wide operating temperature range of -20°C to +60°C (even wider for some models). This means whether in scorching desert heat or frigid northern winters, the device will reliably start and operate, ensuring ELD records are unbroken and drivers can begin or end their shifts on time.

Industry Challenge #3: Inaccurate Positioning and Signal Loss Leading to Fleet Disconnection

The Problem: Trucks often travel through remote areas with weak signals or mountainous terrain, and the metal truck cab itself can shield wireless signals. This frequently leads to inaccurate GPS positioning or cellular network signal loss on consumer tablets. Consequently, dispatch centers cannot track vehicles in real-time, optimize routes, calculate accurate ETAs, or even communicate with drivers during emergencies.

Emdoor Solution: High-Precision GNSS with Antenna Pass-Through Technology

Emdoor's rugged tablets integrate high-performance GNSS (Global Navigation Satellite System) modules, supporting multiple constellations (GPS, GLONASS, Galileo, BeiDou) for fast and precise positioning. Crucially, our vehicle docks support cellular and GPS antenna pass-through technology.

How this solves the challenge:

Centimeter-Level Positioning Accuracy: Through multi-constellation support and advanced positioning algorithms, our devices provide superior positioning accuracy, feeding reliable real-time location data to your Fleet Management System (FMS) for more precise route planning and fuel efficiency analysis.

Always Connected: Antenna pass-through allows external, high-gain antennas from the truck to connect to the tablet, effectively overcoming metal cab signal shielding and significantly boosting cellular network and GPS signal reception. Even in areas with extremely weak signals, your trucks maintain stable communication with dispatch, ensuring critical data transmission and emergency contact.

Industry Challenge #4: Inability to Access Vehicle Diagnostic Data and Limited Peripheral Expansion

The Problem: The core of modern fleet management lies in real-time collection and analysis of vehicle data. Consumer tablets lack the ability to connect to vehicle buses (e.g., J1939, OBD-II), rendering remote diagnostics, predictive maintenance, and driving behavior analysis impossible. Furthermore, a single USB-C port severely limits connectivity with peripherals like receipt printers, ID card readers, and trailer tracking sensors.

Emdoor Solution: Rich I/O Ports and Vehicle Bus Connectivity

Emdoor's rugged tablets and their vehicle docks offer industry-leading rich I/O ports and the capability to connect directly or indirectly to vehicle diagnostic buses.

How this solves the challenge:

Real-time Vehicle Health Monitoring: By integrating support for J1939 or OBD-II bus connectivity, our tablets can collect critical vehicle data like engine RPM, fuel consumption, fault codes, and braking events in real-time. This data is fundamental for predictive maintenance, improving driving behavior, reducing fuel costs, and increasing vehicle uptime.

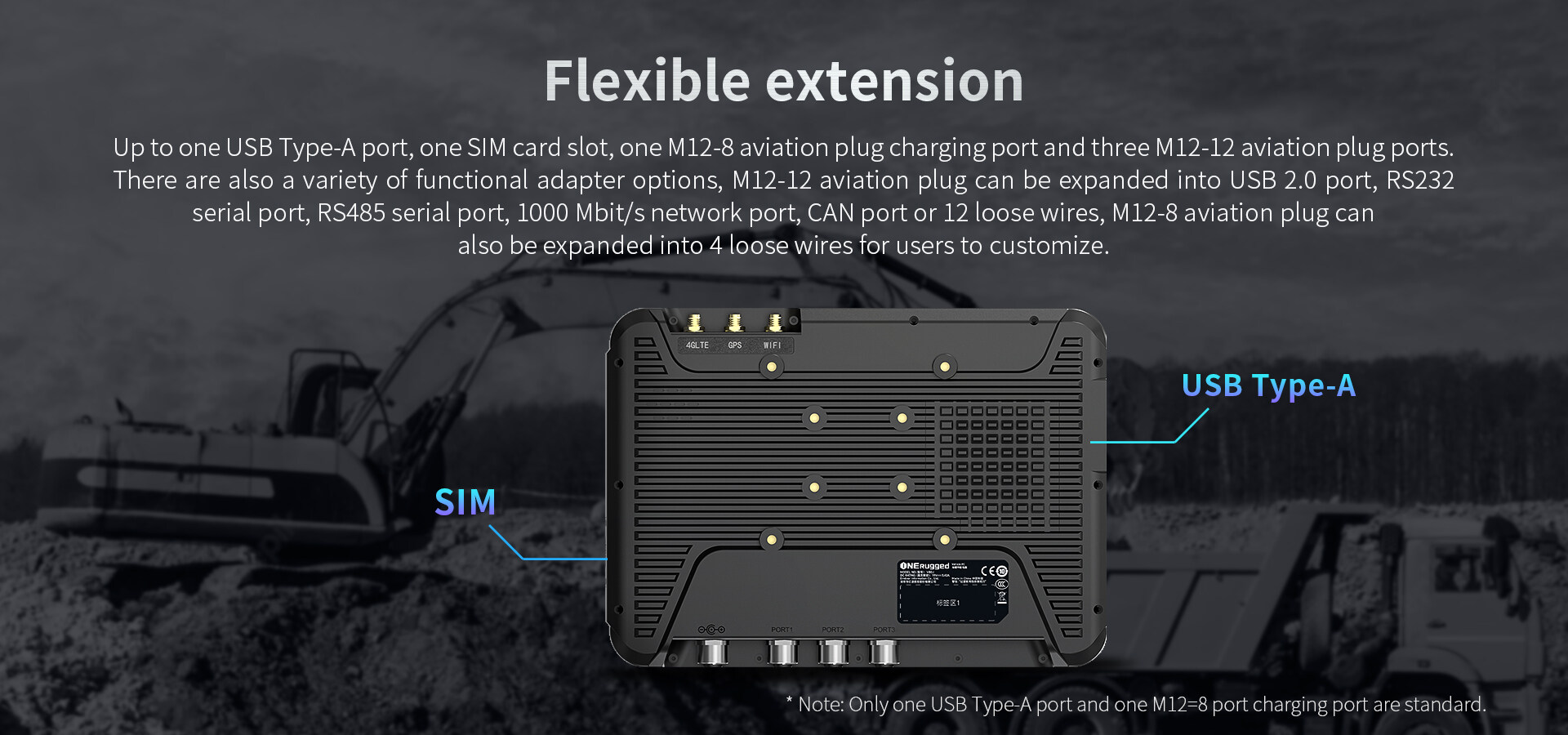

Comprehensive Peripheral Connectivity: Offering multiple RS-232 serial ports, USB-A ports, and Ethernet ports, ensures you can easily connect various industry-specific peripherals such as Bluetooth printers, fingerprint readers, and CAN Bus adapters, transforming the tablet into a true mobile workstation.

Industry Challenge #5: Screen Unreadable in Bright Sunlight and Inconvenient Glove Operation

The Problem: Direct sunlight, glare, and low-light conditions in the truck cab all demand extremely high screen readability. Consumer tablets often lack sufficient brightness and do not support glove operation, forcing drivers to frequently remove and put on gloves when operating the screen or handling cargo, significantly impacting efficiency and driving safety.

Emdoor Solution: Sunlight-Readable High-Brightness Screen with Multi-Mode Touch

Emdoor's rugged tablets are equipped with sunlight-readable, high-brightness screens (typically >800 nits), complemented by anti-glare and anti-reflective coatings. Our touchscreen technology supports glove mode, rain mode, and passive stylus input.

How this solves the challenge:

All-Weather Clear Display: Whether under direct midday sun or in complex lighting conditions within the cab, screen content remains clearly visible, drastically reducing driver distraction and enhancing driving safety.

Unimpeded Operation: Drivers can effortlessly operate the screen without removing heavy work gloves, which is particularly crucial in cold weather or when handling cargo, significantly boosting operational efficiency and comfort.

Industry Challenge #6: Inconvenient Operation While Driving, Increasing Distraction Risk

The Problem: Touchscreen operation requires visual focus, and for a driver, any operation that requires looking down at the screen increases the risk of distraction. Consumer tablets typically have few and fixed-function physical buttons, failing to meet the demand for "blind operation" of complex, high-frequency tasks.

Emdoor Solution: Programmable Physical Buttons

Some of Emdoor's rugged tablets are designed with programmable physical buttons, allowing customers to customize them according to their specific applications and workflows.

How this solves the challenge:

Enhanced Driving Safety: We can map the most frequently used functions, such as "Push-to-Talk" (PTT), "Accept Task," or "Emergency Alert," to physical buttons. Drivers can perform these operations through tactile feedback without taking their eyes off the road, significantly reducing distraction risk while driving.

Optimized Workflows: Customizable buttons simplify complex operational steps, enabling drivers to execute critical tasks more efficiently and safely while on the road.

Industry Challenge #7: Short Product Lifecycles and Difficult Remote Management

The Problem: Consumer tablet products rapidly update and iterate, with models, interfaces, and accessories changing yearly. This creates significant management challenges for fleets when needing to replace or expand devices, leading to inconsistent procurement and incompatible accessories. Moreover, the lack of enterprise-grade remote management capabilities leaves IT departments helpless when a tablet in a truck thousands of miles away encounters software issues.

Emdoor Solution: Long Product Lifecycles and MDM Support

Emdoor deeply understands the long-term and uniformity requirements of fleet deployments. We are committed to providing a stable product lifecycle of 3-5 years, ensuring accessory compatibility. Furthermore, our devices fully support mainstream MDM (Mobile Device Management) solutions.

How this solves the challenge:

Consistent Deployment and Maintenance: A stable product lifecycle means you can procure and deploy devices in phases, ensuring all vehicle docks, chargers, and batteries remain compatible. This greatly simplifies inventory management, IT support, and future upgrade complexities, reducing hidden costs.

Efficient Remote Management: By supporting MDM, your IT team can remotely perform software updates, application deployment, fault diagnosis, data wiping, and device locking for tablets across the country. This significantly reduces vehicle downtime due to device issues, avoiding the hassle and cost of drivers having to return to base for maintenance.

Emdoor: Your Manufacturing Partner for Transportation Mobile Solutions

In the transportation industry, the reliability and efficiency of mobile devices are directly linked to your business lifeline. By choosing Emdoor, you're not just purchasing a rugged tablet; you're investing in a comprehensive solution that supports your ELD compliance, fleet management, driving safety, and operational optimization.

As an experienced manufacturer of rugged tablets, Emdoor, with its outstanding R&D capabilities and customized services, can provide

Military-Grade Quality Assurance: Ensuring devices operate stably and reliably in the most demanding environments.

Superior Performance: Meeting the demands of complex applications and large-scale data processing.

Customized Solutions: Offering products and services tailored to your unique business scenarios.

Full Lifecycle Support: Providing comprehensive guarantees from product design to after-sales service.

Don't let unreliable devices hinder your fleet's progress. Upgrade to Emdoor rugged tablets today to infuse your fleet with on-road intelligence, ensuring every journey is safe, efficient, and compliant.