Smart Retail Industry All-Scenario Solution: Micro Fulfillment Centers (Front Warehouses)

Author: [Emdoor Information Team]Date: January 16, 2026

Introduction: The "Speed War" of the Q-Commerce Era

In the rapidly evolving landscape of modern commerce, "Instant Retail" (or Q-Commerce) has transitioned from a niche luxury to a fiercely contested battleground for e-commerce titans and brick-and-mortar giants alike. The industry standard for delivery has compressed dramatically—from "Next Day Delivery" to "Same Day," and now, to the grueling "30-Minute Delivery" promise. Consumer patience is at an all-time low; they demand gratification instantly.

Behind this war for speed lies the strategic backbone of the Micro Fulfillment Center (MFC), often referred to as the "Front Warehouse." These are small-scale storage facilities located densely within urban centers, serving as the critical hub connecting complex supply chains to the "Last Mile" consumer.

However, the strategic importance of the MFC is matched only by its operational complexity. Constrained by high rent (limiting square footage), massive SKU variety, and unpredictable order spikes, traditional "brute force" labor models are failing. They cannot sustain the extreme efficiency required to pick, pack, and ship an order in under 10 minutes.

How can retail enterprises break through these physical and digital barriers? The answer lies in the total digitization of warehouse operations. This article delves into the deep-seated pain points of MFC operations and provides a comprehensive analysis of Emdoor Information’s Full-Scenario Intelligent Solution, leveraging rugged smart hardware combined with advanced WMS (Warehouse Management Systems) to redefine retail efficiency.

I. Critical Analysis: The Operational Dilemma of Traditional Front Warehouses

While the MFC model theoretically solves the distance problem by placing goods closer to the customer, the practical execution is fraught with challenges. Without digital intervention, the high-velocity nature of Q-Commerce exposes four fatal flaws in traditional operations:

1. The Inventory Data "Black Box"

In legacy systems utilizing paper-based picking lists or non-integrated PDAs, data entry lags behind physical movement. This latency creates a "Black Box" effect where the WMS (Warehouse Management System) shows an item is in stock, but the physical bin is empty. The result? Overselling. Canceling a customer's order due to stockouts not only results in lost revenue but causes irreparable damage to brand loyalty.

2. The "Maze" of Inefficient Picking

During peak hours (e.g., lunch rushes or evening commute windows), order density explodes. Without intelligent path planning, pickers rely on memory to navigate the warehouse. This leads to chaotic movement, backtracking, and excessive walking distance. In an industry where seconds count, an inefficient path can mean missing the delivery window.

3. Suboptimal Space Utilization

Urban real estate is expensive. Traditional MFCs often suffer from poor bin management, where goods are stored randomly based on convenience rather than logic. This lowers the storage density per square foot and complicates the replenishment process, as high-turnover items may be buried behind slow-moving stock.

4. High Labor Dependency and Turnover

The warehousing sector faces notoriously high turnover rates. Traditional workflows rely heavily on "tribal knowledge"—experienced workers who know where everything is. When these workers leave, operational efficiency plummets. Training new staff to memorize thousands of SKUs and bin locations takes weeks, a luxury that fast-paced retail cannot afford.

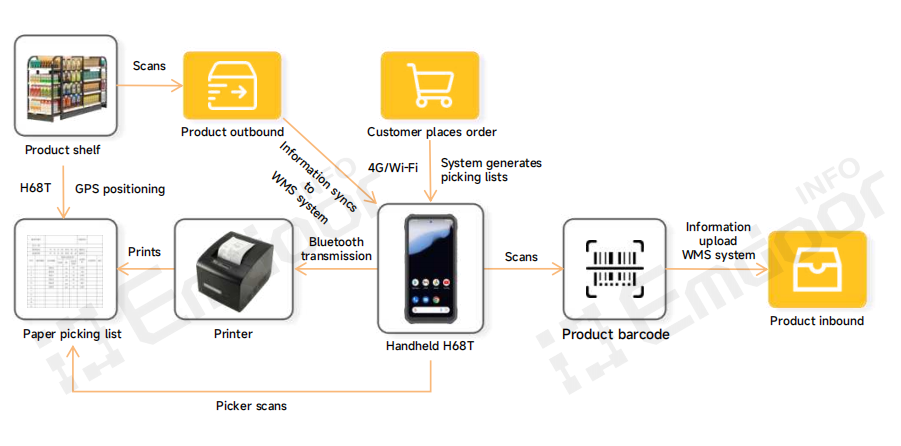

II. Scenario 1: Inbound & Outbound Management — The Digital Engine of Precision Fulfillment

Inbound and outbound operations are the heartbeat of the MFC. They must be fluid, accurate, and fast. Emdoor Information addresses this with a solution centered on the Rugged Handheld Terminal H68T.

1. Digitized Inbound: Eliminating Errors at the Source

The accuracy of the entire supply chain depends on the receiving dock.

The Workflow: When goods arrive at the MFC, staff use the H68T to scan incoming pallets and individual items.

The Tech: The H68T features a top-mounted, professional-grade barcode scanning engine. It is calibrated to read damaged, stained, or shrink-wrapped barcodes instantly.

The Impact: Data is synchronized to the WMS via 4G or Dual-Band Wi-Fi in real-time. This "Receive-to-Available" workflow ensures that the moment a product enters the warehouse, it is visible on the consumer app, maximizing sales potential.

2. Intelligent Picking: Redefining the "Golden Path"

Once a user places an order, the clock starts ticking. The system pushes an Electronic Picking List directly to the H68T.

Algorithmic Navigation: Leveraging built-in GPS and indoor positioning compatibility, the device guides the picker along the mathematically optimal route. It sequences items to ensure heavy items are picked first (to prevent crushing) and minimizes travel distance.

Scan-to-Verify: To prevent the nightmare of delivering the wrong item, the picker must scan the item barcode at the bin. The H68T performs a local validation; if the barcode doesn't match the order, the device vibrates and alerts the user audibly.

Seamless Hand-off: The H68T supports Bluetooth connectivity to portable belt printers. Pickers can generate shipping labels and receipts right at the packing station, closing the loop instantly.

[Image Placeholder: Alt Text="Emdoor Info H68T Rugged Handheld Terminal displaying an optimized picking route map in a warehouse aisle."]

Hardware Spotlight: The H68T Rugged Handheld

Display: A 6.56-inch HD High-Brightness screen. Crucially, it supports Wet Hand and Glove Touch modes, making it ideal for Fresh Food (Cold Chain) sections where condensation and gloves are common.

Power: Equipped with a 5800mAh battery and 33W fast charging. It is designed to survive a "Double 11" or "Black Friday" shift without needing a mid-shift swap.

Ruggedness: Certified IP68 (dust and water resistant) and drop-tested from 1.5 meters. In a frantic warehouse environment, devices will be dropped. The H68T ensures a drop doesn't mean downtime.

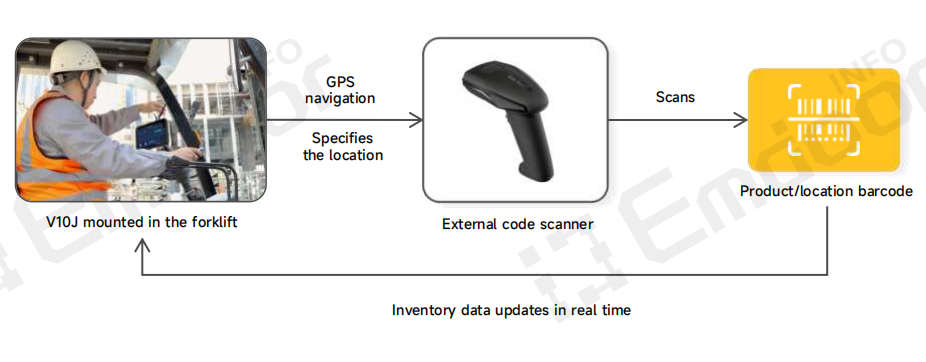

III. Scenario 2: Smart Shelving & Replenishment — The "Brain" of Forklift Operations

For larger MFCs or centralized hubs that utilize high-bay racking and pallets, forklifts are the primary movers. However, a forklift without data is just a vehicle; a forklift with data is a strategic asset.

1. The Intelligent Forklift Upgrade

Emdoor Information transforms standard material handling equipment into "Smart Forklifts" by retrofitting them with the Vehicle Mount Computer V10J. Securely mounted via a heavy-duty bracket, the V10J serves as the driver's command center.

2. Visualized Put-Away Strategy

Smart Allocation: The WMS analyzes the attributes of incoming SKUs (turnover rate, weight, expiry date). It assigns a dynamic bin location—fast movers near the dock, slow movers higher up.

Guided Navigation: The V10J, equipped with GPS/Glonass/BeiDou navigation, guides the driver to the exact aisle and bay. This eliminates the "search time" where drivers wander looking for empty space.

3. The "Pull" Replenishment Model

In Q-Commerce, an empty shelf in the picking area means lost sales.

The Trigger: When the picking area stock dips below a safety threshold, the system automatically generates a replenishment task.

The Action: The V10J alerts the nearest forklift driver with a pop-up priority task: "Move Pallet A to Picking Zone B." This proactive, pull-based replenishment ensures that pickers never face an empty bin.

[Image Placeholder: Alt Text="Emdoor Info V10J Vehicle Mount Computer installed on a forklift, showing real-time inventory map and replenishment tasks."]

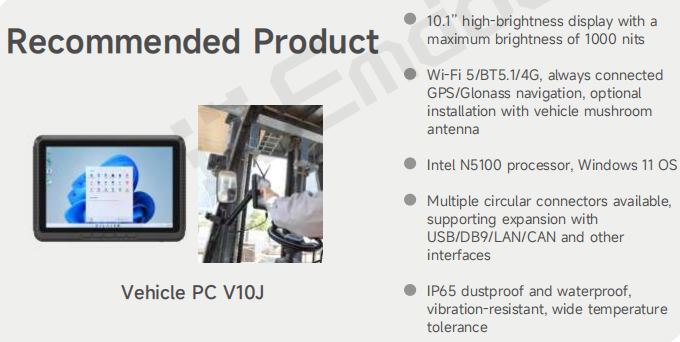

Hardware Spotlight: The V10J Vehicle Mount Tablet

Visibility: A 10.1-inch screen with optional 1000 nits high brightness. This is critical for forklifts that move between dark indoor aisles and bright outdoor loading docks.

I/O Connectivity: Features a rich array of ports (USB, DB9 Serial, LAN, CAN Bus). This allows for hardwired connections to long-range scanning guns, allowing drivers to scan barcodes from the cab without dismounting—a massive safety and efficiency gain.

Durability: Rated IP65 with Military-Standard shock and vibration resistance (MIL-STD-810H). It withstands the constant shaking of a forklift and the temperature fluctuations of cold storage.

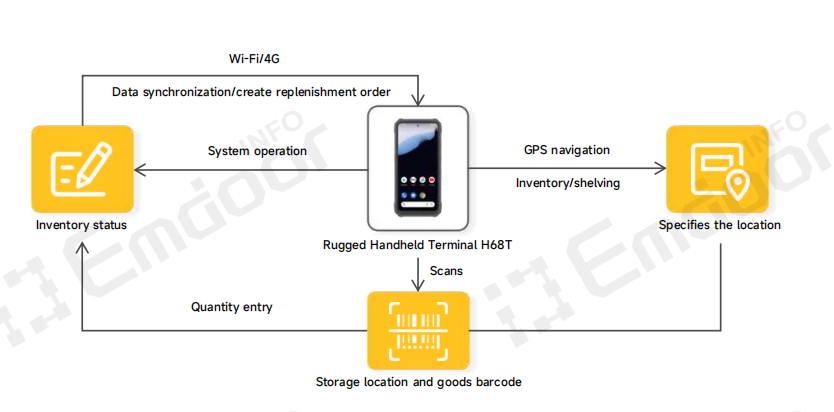

IV. Scenario 3: Inventory Management — From "Annual Shut-down" to "Dynamic Cycle Counting"

Inventory accuracy is the bedrock of profitability. Traditional methods often require shutting down the warehouse for a full day to count stock ("Wall-to-Wall" counts), which is impossible in a 24/7 retail environment.

1. Dynamic Cycle Counting

Using the H68T, the MFC adopts a "Cycle Counting" methodology. The WMS generates daily tasks to count specific, high-risk, or high-value bins during downtime.

2. Real-Time Variance Analysis

As staff scan bin locations and item quantities, data flows instantly to the backend.

Immediate Resolution: If a discrepancy is found (e.g., System says 10, Physical says 8), the system flags it immediately for a recount or adjustment.

Loss Prevention: This rapid identification helps managers pinpoint when and where loss is occurring (theft, damage, or vendor error) rather than discovering it months later.

3. Supply Chain Visibility

Accurate local inventory data feeds upstream. Procurement teams can automate reordering based on precise data, preventing overstocking of perishable goods. Simultaneously, downstream sales platforms (Apps/Websites) reflect accurate "Available to Promise" (ATP) quantities, boosting customer trust.

V. Summary: Building a Resilient, High-Velocity Supply Chain

The Emdoor Information Smart Micro Fulfillment Solution is not merely a collection of hardware; it is a catalyst for Operational Digital Transformation.

By integrating the H68T Rugged Handheld and V10J Vehicle Mount Computer into the very fabric of warehouse workflows, retail enterprises unlock three tiers of value:

Fulfillment Velocity: Path optimization and digital guidance slash minutes off every order, making the "30-minute promise" a sustainable reality.

Cost Structure Optimization: By reducing reliance on tribal knowledge and minimizing error rates (returns/reshipments), the Total Cost of Ownership (TCO) decreases significantly.

Data-Driven Agility: Real-time visibility allows management to pivot instantly—adjusting staffing for predicted peaks or clearing out slow-moving inventory before it expires.

As the industry moves toward AI-driven visual recognition and autonomous mobile robots (AMRs), the front warehouse will continue to evolve. Emdoor Information remains committed to providing the rugged digital infrastructure that powers this evolution, helping retailers win the race for the last mile.

Frequently Asked Questions (FAQ)

Q1: How does the H68T handle battery life during double shifts?

A: The H68T is engineered for endurance. It features a 5800mAh high-density battery optimized by power-efficient processors. It supports 33W fast charging, allowing it to regain significant charge during a lunch break. For 24/7 operations, the device is designed to be charged quickly or swapped, ensuring zero downtime.

Q2: Can the V10J Vehicle Mount operate in sub-zero cold storage environments?

A: Yes. The V10J is built with industrial-grade components capable of wide-temperature operation. It functions reliably in freezing cold storage environments (often down to -20°C or lower with heater options) and resists the condensation issues that plague consumer-grade tablets, thanks to its IP65 sealing.

Q3: Is this solution compatible with my existing WMS/ERP (e.g., SAP, Oracle, Blue Yonder)?

A: Absolutely. Emdoor Information’s devices run on standard, enterprise-ready operating systems (Android 11/12+ or Windows 11). They support standard APIs and terminal emulation (TE) clients, making them compatible with virtually all major WMS, ERP, and proprietary backend systems.

Q4: Why choose rugged hardware over cheaper consumer smartphones?

A: While consumer phones have a lower upfront cost, their Total Cost of Ownership (TCO) is much higher in industrial settings. Consumer devices fail rapidly due to drops, dust, and moisture. They lack professional scanning engines (slow focusing) and have short lifecycles (EOL in 1-2 years). Emdoor's rugged devices last 3-5+ years, survive daily abuse, and guarantee long-term support, resulting in a much lower cost over time.