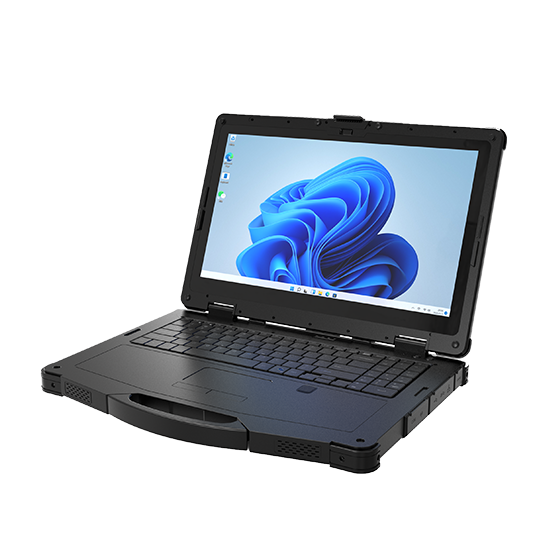

In today’s fast-paced manufacturing and engineering industries, where precision, reliability, and real-time performance are mission-critical, Industrial rugged computer are setting a new standard for operational excellence. These powerful and durable devices are transforming how factories, production lines, and engineering facilities operate — driving higher productivity, better data visibility, and smarter automation.

Precision Meets Durability: A Strategic Alliance

The synergy between precision technology and rugged durability lies at the heart of modern industrial transformation. On manufacturing floors and engineering sites, where fine measurements, complex calculations, and real-time control systems are essential, rugged industrial computers provide the resilience needed to maintain uninterrupted operations.

Built to withstand dust, shock, vibration, and extreme temperatures, industrial-grade computers ensure consistent and stable performance in even the harshest factory environments.

Key Advantages:

Maintain stable performance under heavy workloads

Support precise calculations and complex processes

Shop Floor Warriors: Rugged Computers in Real Industrial Action

On the shop floor, industrial rugged computers act as the backbone of manufacturing operations. From CNC machining to automated assembly lines, these durable PCs are engineered to perform reliably under continuous vibration, heavy machinery noise, and potential impact.

They support operators in monitoring production workflows, tracking machine performance, and ensuring product accuracy at every stage — making them indispensable tools for modern smart factories.

Applications:

CNC machining centers

Equipment monitoring and production tracking

Real-Time Monitoring and Control: Driving Efficiency

A key strength of rugged computers is their real-time monitoring and control capability. Equipped with advanced sensors, connectivity modules, and rugged interfaces, these devices can seamlessly integrate with existing machinery and production systems.

Monitor critical parameters live

Detect anomalies immediately

Adjust operations to reduce downtime

This level of operational visibility allows manufacturers to minimize disruptions and maintain optimal production output.

Data-Driven Decision Making: Unlocking Productivity

Modern manufacturing is increasingly data-driven, and rugged industrial computers are essential to processing and analyzing massive volumes of production data.

With high-performance processors and industrial-grade reliability, these computers support:

Predictive maintenance strategies

Automated quality control

Production optimization through analytics

This not only increases efficiency but also enables management to make faster and more accurate operational decisions, ensuring smooth and scalable manufacturing growth.

Integration with IoT and Industry 4.0: A Technological Synergy

Industry 4.0 and the Internet of Things (IoT) are reshaping the industrial landscape — and rugged computers are at the center of this transformation. By integrating with connected sensors, robots, and smart systems, these computers enable:

Seamless communication across equipment

Real-time data exchange

Automated and adaptive manufacturing environments

This technological synergy enhances flexibility, reduces errors, and improves responsiveness on the factory floor, making rugged computers the core infrastructure of smart manufacturing.

Building a Resilient Future with Rugged Industrial Computing

The deployment of industrial rugged computers in manufacturing and engineering is more than just a technical upgrade — it’s a strategic investment in durability, precision, and innovation.

These systems:

Ensure operational stability in challenging environments

Enable real-time control and data-driven optimization

Support Industry 4.0 and IoT adoption

Extend equipment lifespan and reduce total cost of ownership

As manufacturing becomes more automated, intelligent, and data-centric, the partnership between durability and computing power will continue to define the next generation of industrial excellence.

You may also be interested in these products: