From Workshop to Roadside: Emdoor Rugged Tablet Ensures Zero-Downtime Automotive Key Programming

Originally by: Emdoor Marketing Center | June 20, 2025

In the high-stakes world of automotive key programming and cloning, mobility and reliability are not just conveniences; they are the bedrock of the business. For technicians on the front lines, the ability to perform complex electronic procedures on-site—whether in a pristine workshop, a dusty parking lot, or on the side of a road—is paramount. This is the story of how a global industry leader met the challenges of field service head-on with a purpose-built technology solution.

When Keyline, a world-renowned provider of automotive key programming solutions, connected with Emdoor Information at a trade show, they were seeking more than just a new piece of hardware. They needed a robust, reliable, and seamlessly integrated mobile terminal to power their sophisticated operations. Their ultimate choice, the Emdoor EM-I87J rugged tablet, has since transformed their workflow.

"The Emdoor EM-I87J rugged tablet has significantly improved our work efficiency and stability. Its exceptional durability, diverse interface configuration, and high compatibility ensure reliable operation in complex environments. Overall, this tablet has become an indispensable tool in our workflow, helping us provide superior service to our customers."

— Technical Supervisor, Keyline

Let's delve into the challenges Keyline faced and explore how the Emdoor EM-I87J became the definitive solution.

The Client: Keyline – A Legacy of Precision Meets Modern Challenges

With a rich history tracing back to the 18th century, Keyline, an Italian enterprise, has evolved into one of the world's foremost experts in solutions for key cloning and programming. They are synonymous with precision, quality, and innovation in the locksmith and automotive service industries.

As vehicle control systems have grown exponentially more complex, Keyline has continuously expanded its integrated hardware and software solutions to stay ahead of the curve. However, this expansion into highly mobile, on-site service models brought a new set of operational hurdles that standard commercial technology was ill-equipped to handle.

The Bottleneck: When Commercial Tech Fails in the Field

Keyline's technicians are mobile problem-solvers. Their "office" changes daily, and their work demands a tool that can withstand the rigors of the real world. Their existing reliance on commercial-grade tablets created three critical bottlenecks.

1. The Hostile Work Environment

Key programming doesn't always happen in a clean, controlled setting. Technicians frequently work in garages with concrete floors, outdoor parking lots exposed to the elements, and roadside locations. These environments present constant threats to fragile electronics:

Impact and Drops: Accidental drops are inevitable. A commercial tablet, even in a case, is unlikely to survive repeated impacts, leading to costly downtime and data loss.

Frequent Handling: The process involves constant plugging and unplugging of cables and peripherals, placing immense strain on flimsy consumer-grade ports.

Dust and Debris: Workshops and outdoor settings are filled with dust and fine particles that can easily infiltrate a standard tablet's chassis, causing internal damage and failure.

These factors led to frequent interruptions and a lack of operational stability, directly impacting the technician's ability to complete jobs efficiently.

2. The Connectivity Maze

A single key programming job is a multi-step, multi-device process. It requires a seamless flow of data between the original key, the vehicle's onboard computer, and the programming software. This necessitates connecting a variety of external devices:

884 MINI DECRYPTOR: The core device for reading the original key's chip.

Specialized Programming Cables: To connect to the vehicle's On-Board Diagnostics (OBD) port.

Remote Control Modules: For programming the key's remote functions.

A typical commercial tablet, with its limited one or two ports, simply cannot accommodate this ecosystem without a tangle of unreliable dongles and hubs. This "dongle nightmare" introduces multiple points of failure and complicates the entire procedure.

3. Performance Under Pressure

Keyline’s proprietary Cloning Tool software is a powerful, specialized application. It handles complex cryptographic data, communicates with vehicle control units, and manages a vast database of vehicle makes and models. The software demands a high degree of responsiveness and processing power. Any lag, system freeze, or crash during a critical data-writing process could "brick" a key or even damage the vehicle’s immobilizer system. Furthermore, an inability to connect to a 4G network for remote technical assistance could leave a technician stranded and unable to complete a difficult job, damaging both their efficiency and the company's reputation.

Keyline needed a single, integrated mobile terminal that was durable, highly connected, and powerful enough to guarantee a smooth, uninterrupted workflow.

The Solution: EM-I87J – The Purpose-Built Field Terminal

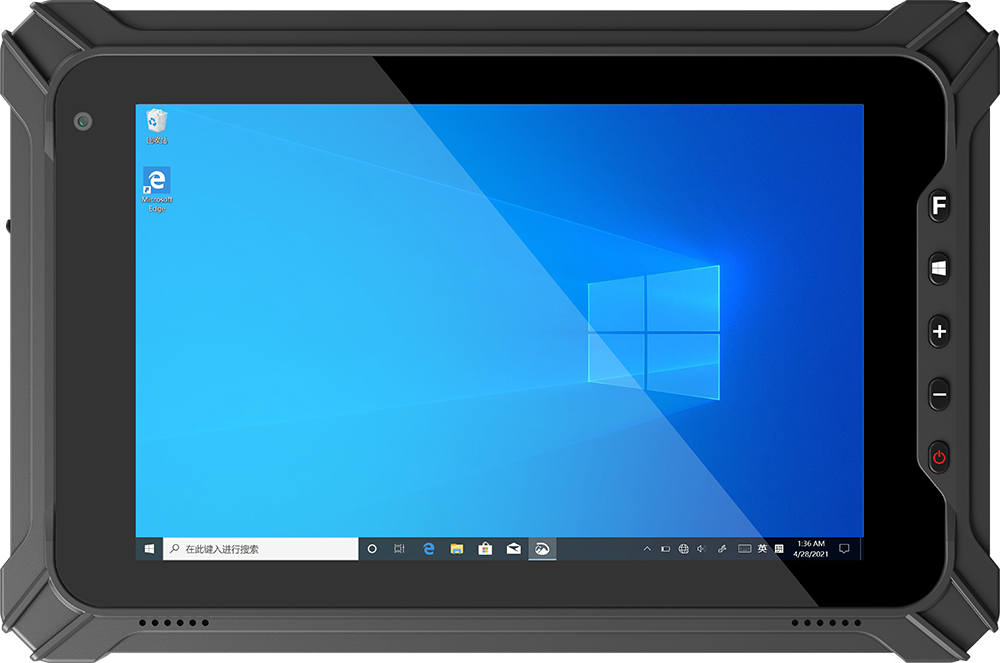

After a thorough evaluation, Keyline integrated the Emdoor EM-I87J rugged tablet computer into its Automotive Programming Kit. It serves as the central hub—the brain of the entire on-site operation, running the critical software that drives every step of the process.

The EM-I87J directly addressed every one of Keyline’s pain points:

Unyielding Durability for Uninterrupted Tasks: The EM-I87J is built for the field. With an IP65 rating, it is fully protected against dust ingress and resistant to water jets, making it ideal for messy workshops and unpredictable weather. Its superior drop resistance and wide operating temperature range ensure it maintains high stability and performance no matter the environment. The high-hardness, high-brightness touchscreen remains crystal clear and responsive even under direct sunlight, providing a precise and frustration-free user experience.

Diverse Connectivity for Complex Vehicle Operations: The EM-I87J eliminates the connectivity maze. It is equipped with a versatile array of ports, including USB 3.0 Type-A and Type-C, allowing for high-speed wired connections to the 884 MINI decoder and other peripherals. Simultaneously, its built-in WiFi, Bluetooth, and 4G LTE modules provide robust wireless options. This means technicians can transfer data instantly, connect to peripherals without cables, and access remote technical support and online databases even when no local network is available, adding a new dimension of flexibility to their service.

Perfect Hardware-Software Synergy: Powered by an Intel® Celeron N5100 processor and running the stable Windows 10 operating system, the EM-I87J provides the perfect platform for Keyline’s demanding software. This deep hardware and software optimization ensures the entire key programming and vehicle diagnostic process runs smoothly, without lag or interruption. This synergy transforms the tablet from a simple display screen into a fully integrated, intelligent work terminal.

The Workflow Reimagined: A Seamless Process from Start to Finish

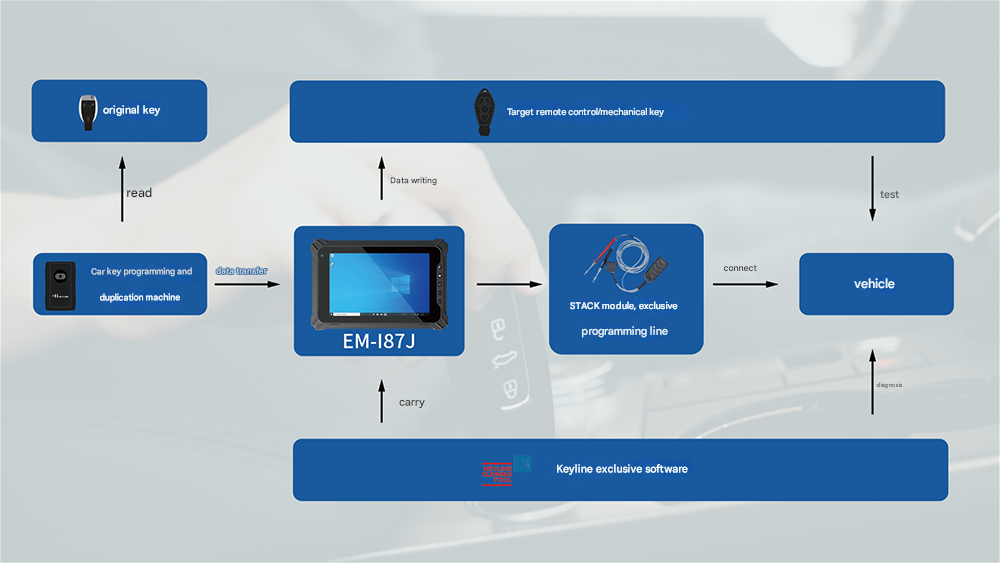

With the Emdoor EM-I87J at its core, the Keyline Automotive Programming Kit delivers a flawless field experience.

1. The Read Operation:A technician begins by using the 884 MINI DECRYPTOR to read the encrypted data from the original key's transponder chip. This data is then transferred instantly—via a stable Bluetooth or high-speed USB connection—to the EM-I87J tablet.

2. Data Processing and Vehicle Connection:The powerful Keyline software on the tablet immediately processes and analyzes the data. The technician selects the correct vehicle make and model from the intuitive interface. Using the STACK interface module and a vehicle-specific programming cable, they connect the EM-I87J directly to the target vehicle's OBD port.

3. The Write Operation:The Keyline software initiates a diagnostic procedure, securely extracting security data from the vehicle's control unit. Once diagnostics are complete, the technician can choose to either clone the original key or program a brand-new one. The EM-I87J then securely writes the necessary data to the new transponder chip and remote.

4. Verification and Archiving:Finally, the technician performs an on-site test, verifying that the new key's remote functions and ignition capabilities work perfectly. All operational data from the entire process is automatically saved within the Keyline software on the tablet, creating a detailed record for future technical traceability and remote analysis.

This entire process, from initial reading to final verification, is performed smoothly and without interruption, thanks to the reliability and power of the Emdoor EM-I87J. It has transformed a potentially fraught and complex procedure into a streamlined, efficient, and professional service delivery. For Keyline and their customers, this means less time on-site, higher success rates, and unparalleled confidence in every job.