Introduction

In the fourth chapter of our Smart Manufacturing Solutions series, we explore Equipment Predictive Maintenance, a crucial factor in ensuring long-term production efficiency and equipment reliability. By leveraging industrial smart terminals and rugged devices, Emdoor Information enables manufacturers to achieve intelligent lifecycle management of equipment. This not only reduces operations and maintenance (O&M) costs but also enhances production continuity.

This chapter will cover three core scenarios: predictive maintenance, equipment inspection, and asset management. Together, these solutions form the backbone of a proactive maintenance strategy that drives efficiency and productivity.

Predictive Equipment Maintenance: From Reactive to Proactive

Traditional maintenance models often rely on scheduled servicing or repair after failure. While common, this reactive approach leads to low equipment utilization rates and high costs associated with unplanned downtime.

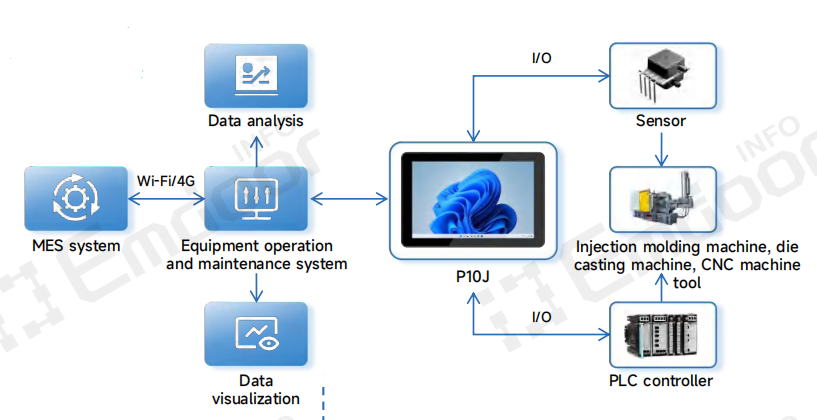

Emdoor Information offers a smarter approach through the deployment of industrial panel PCs such as the P10J. These rugged devices feature multiple I/O interfaces, making it possible to connect sensors that capture real-time operational data such as:

- Temperature

- Vibration

- Current measurements

The data is transmitted via Wi-Fi to the equipment maintenance system, enabling early fault detection and health monitoring.

Key Phases of Predictive Maintenance

- Data Acquisition – Sensors collect live equipment data.

- Real-Time Analysis – The system evaluates performance trends.

- Alert Distribution – Automatic notifications are sent when abnormalities are detected.

- MES Integration – Seamless connection with the Manufacturing Execution System.

This proactive method prevents costly breakdowns, minimizes downtime, and extends the overall lifecycle of equipment.

Intelligent Equipment Inspection: Accuracy and Efficiency Combined

Manual inspections often suffer from low efficiency, missed checks, and tool incompatibility, resulting in gaps in operational safety.

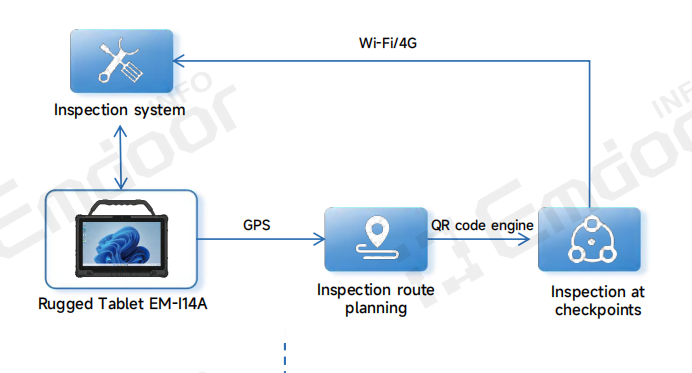

To address these challenges, Emdoor Information provides the I14A rugged tablet, powered by Intel Core i5/i7 processors. Its high-performance design supports precise data capture and robust field operations. Key features include:

- Hot-swappable dual batteries for uninterrupted operation.

- NFC module integration for streamlined inspection processes.

- Rugged durability to withstand harsh environments.

By digitizing the inspection process, manufacturers gain traceability of inspection data and improve accuracy rates, ensuring that no issues are overlooked.

Asset Management: Full Lifecycle Digital Control

Traditional asset management methods are time-consuming and prone to data delays and information silos, creating inefficiencies in modern factories.

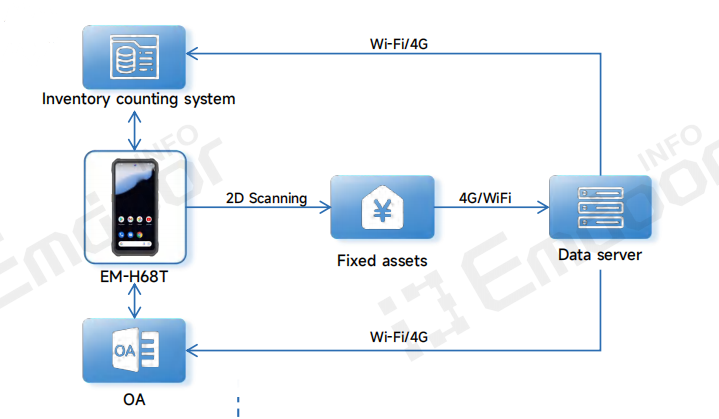

The Emdoor Information H68T Rugged Handheld Terminal is purpose-built to overcome these barriers. Equipped with a long-range scanning engine, it quickly reads equipment barcodes and uploads data in real time via 4G/Wi-Fi. Its compatibility with EMS and OA systems eliminates data silos by unifying workflows.

Key Advantages of the H68T

- IP68-rated protection for use in demanding environments.

- Operates in extreme temperatures from -20℃ to 60℃.

- 6.56-inch glove-friendly touchscreen designed for field operations.

- Achieves 80% improvement in inventory efficiency.

- Delivers 99.9% data accuracy for asset records.

With these capabilities, the H68T enables enterprises to implement digital lifecycle management of assets, from acquisition and usage to maintenance and retirement.

Conclusion

The Equipment Predictive Maintenance sector represents a major leap forward for industrial enterprises. By integrating predictive monitoring, intelligent inspections, and digital asset management, Emdoor Information empowers manufacturers to achieve:

- Real-time visualization of equipment status.

- Proactive fault detection and prevention.

- Refined and efficient management across the full equipment lifecycle.

This holistic approach not only reduces costs but also enhances operational efficiency, ensuring continuous and reliable production in the era of smart manufacturing.