Smart Manufacturing Solutions: Chapter 3 - Quality Inspection and Traceability in Smart Manufacturing

In this third chapter of our smart manufacturing series, we focus on Quality Inspection and Traceability, two key components driving the success of intelligent manufacturing. In today’s fast-paced and competitive manufacturing environment, ensuring product quality and seamless traceability is critical. Emdoor is committed to enhancing product quality management through AI and intelligent technologies, enabling full-process traceability from production to post-sale.

The Role of Quality Inspection and Traceability in Smart Manufacturing

Quality inspection is the backbone of any manufacturing operation. It ensures that products meet the required standards before they reach the consumer. However, traditional manual inspection methods are often plagued by challenges such as high labor costs, inconsistency, and human error.

By integrating AI technologies, Emdoor rugged mobile computers and industrial panel PCs provide automated solutions that not only improve inspection efficiency but also enable complete traceability throughout the production cycle. This innovation reduces operational costs, boosts productivity, and helps manufacturers meet the ever-increasing demand for precision and reliability.

Key Scenarios for Quality Inspection and Traceability

Emdoor quality inspection and traceability solutions focus on two main scenarios: AI & AOI Automated Inspection and Quality Process Control. These solutions combine AI-powered visual inspection with real-time traceability, improving overall product quality and reducing the risk of defects.

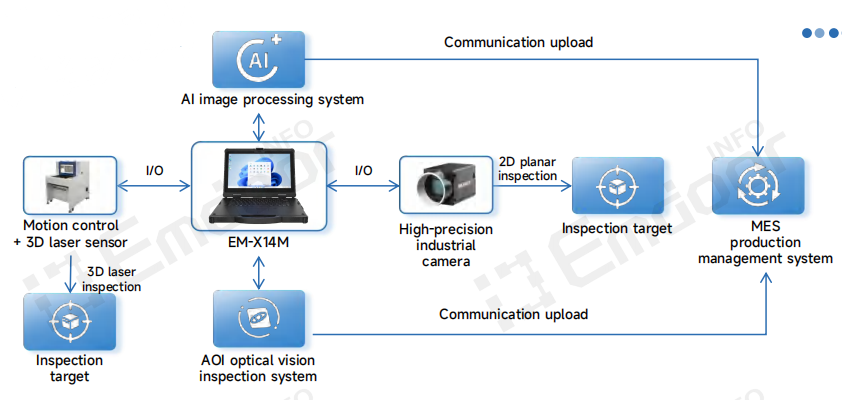

AI & AOI Automated Inspection: Revolutionizing Quality Control

Traditional manual inspection methods are time-consuming and prone to errors. This often results in missed defects, incorrect inspections, and ultimately a lower yield rate. Emdoor AI & AOI (Automated Optical Inspection) technology addresses these issues by automating the inspection process using deep learning algorithms and 3D stereo inspection.

Our AI Rugged Notebook EM-X14M, powered by Intel Core Ultra processors, integrates with industrial cameras and AOI equipment for high-precision inspections. This solution works through four key phases:

Model Training: Teaching the AI system to recognize defects.

Image Capture: Using industrial cameras to capture high-resolution images of products.

Defect Identification: The AI algorithm analyzes the images and identifies defects.

Real-Time Alerts: Instant notifications are triggered for any detected defects.

Key Benefits of the AI & AOI Solution:

Improved inspection efficiency: Faster and more accurate inspections than manual methods.

Reduced false/missed inspections: AI ensures that no defects are overlooked.

Full traceability: Every inspection is logged, creating a detailed history for each product.

By leveraging these technologies, manufacturers can achieve higher-quality products, increase operational efficiency, and reduce product defects.

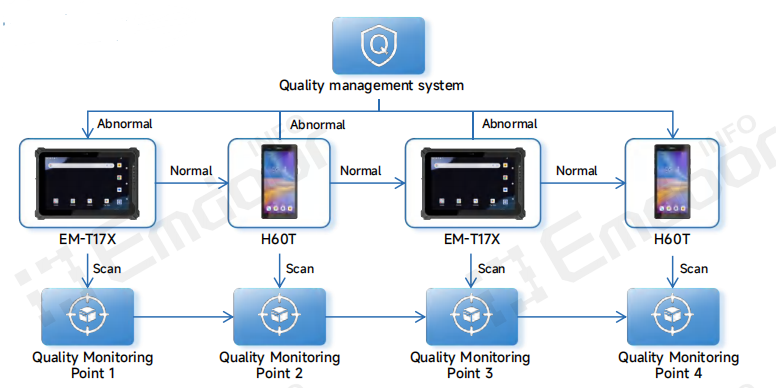

Quality Process Control: Ensuring End-to-End Quality Management

In traditional production systems, quality inspections are often inconsistent, leading to errors and difficulties in tracing the source of defects. With Emdoor rugged mobile terminals, manufacturers can implement comprehensive quality control processes that span the entire production cycle—from order dispatch and quality verification to final product documentation.

Our rugged mobile terminals facilitate the following processes:

Order Dispatch: Ensuring that the correct order is sent to the right production line.

QR Code Verification: Scanning QR codes to ensure the product matches the production specifications.

Quality Documentation: Digitally recording quality checks and linking them to the corresponding batch.

Real-Time Data Upload: Automatically uploading inspection results to the cloud-based system for traceability.

When post-sale quality issues arise, a simple QR code scan enables manufacturers to instantly trace the product back to its source, ensuring fast and accurate resolution. This solution provides several core benefits:

Improved Inspection Efficiency: Real-time data collection reduces inspection time.

Enhanced Production Quality: Helps prevent the production of non-conforming products.

Traceability: Allows manufacturers to easily track product quality throughout the production process.

Emdoor Commitment to Smart Manufacturing Innovation

By integrating advanced technologies like AI, deep learning algorithms, and rugged industrial computing devices, Emdoor Information is transforming the way manufacturers approach quality control. Our solutions empower manufacturers with real-time insights into their production processes, enabling them to maintain high-quality standards and achieve full-process traceability.

As industries evolve and demand for smart manufacturing solutions increases, Emdoor is committed to providing the tools manufacturers need to stay ahead of the curve. From automated inspection to end-to-end traceability, our solutions help drive productivity, reduce costs, and enhance product quality.

Ready to Empower Your Manufacturing with Smart Solutions?

As the manufacturing landscape becomes increasingly competitive, companies must adapt to stay relevant. Emdoor Information’s smart manufacturing solutions—including AI & AOI automated inspection and quality process control—provide the necessary tools to ensure product excellence and operational efficiency.

If you are ready to explore how Emdoor Information can support your digital transformation and enhance quality management, contact us today. Let’s work together to optimize your production processes and drive smart manufacturing forward.