Revolutionizing Workshop Operations with Industrial Automation

As industries continue to embrace digital transformation, smart manufacturing has become integral to improving efficiency, reducing downtime, and enhancing production processes. In this second chapter of our smart manufacturing solutions series, we will focus on one of the core components of smart manufacturing—workshop industrial automation. We’ll explore five key scenarios where Emdoor 's rugged industrial computing devices enable seamless automation and operational optimization: equipment automation control, MES production execution, ESOP work instructions, real-time production dashboards, and mobile workstations.

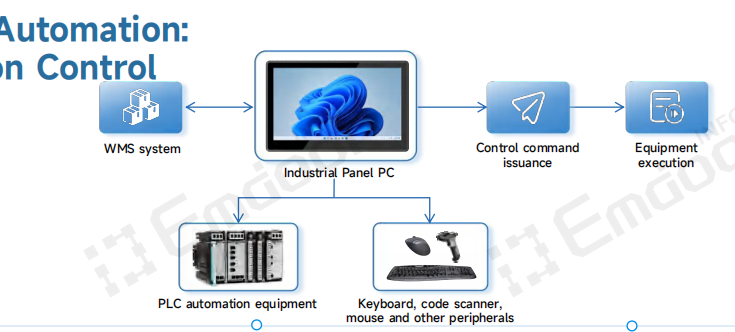

Equipment Automation Control - Real-Time Monitoring and Control

In traditional manufacturing environments, equipment status is often not collected and controlled in real time. This lack of monitoring leads to delayed responses from scheduling systems, which significantly affects the efficiency and stability of the production line.

Emdoor's Industrial Panel PCs for Real-Time Production Control

Emdoor industrial panel PCs are designed to handle tough workshop environments. With an IP65-rated front panel, these devices are equipped for wide temperature tolerance, pressure resistance, and electromagnetic interference protection. When integrated with the MES system, they facilitate real-time data transmission, enabling optimized production scheduling. Featuring high-performance processors and industrial interfaces, including RJ45/RS232, our panel PCs support seamless PLC communication via touch controls and wireless connectivity, allowing precise equipment monitoring and control.

Our recommended models for this scenario include the P10A, P15A, and P21A, which offer multiple mounting options to accommodate a variety of workstation requirements.

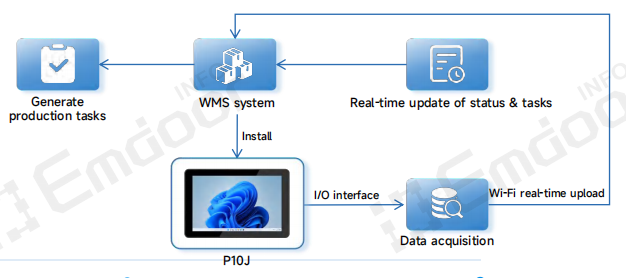

MES Production Execution - Optimizing Flexible Production Processes

In flexible production modes, traditional management systems often face data lag and execution gaps, leading to inefficiencies in task execution.

Panel PCs for Seamless MES Integration

Emdoor’s panel PCs are deployed at workshop stations, seamlessly integrated with MES systems to enable real-time task dispatching and data collection. This integration provides full-process production visualization and helps improve manufacturing efficiency. Our solutions are available for wall-mounted or arm-mounted installations, ensuring flexible configuration. With Intel Celeron processors and IP65-rated front panels, these devices perform reliably even in harsh environments. Continuous monitoring of work order progress and production data ensures rapid identification of bottlenecks, optimizes resource allocation, and enhances both product consistency and manufacturing efficiency.

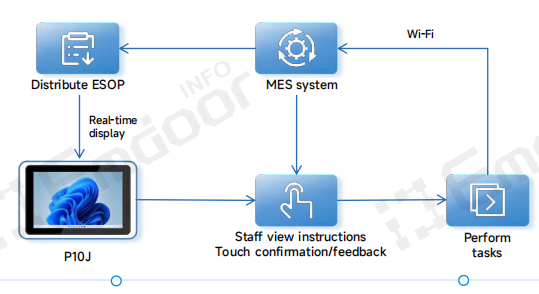

ESOP Work Instructions - Eliminating Paper-Based Inefficiencies

Traditional paper-based work instructions lead to challenges such as untimely updates, version confusion, and operational inefficiencies.

Real-Time Work Instructions with Emdoor Panel PCs

With Emdoor’s P10J, P15J, and P21J panel PCs, we integrate with your enterprise ESOP system to deliver electronic work instructions in real time. These devices ensure that each operation step is accurate and timely, improving communication and coordination across the production floor. Equipped with high-definition touch displays, our devices offer multiple display modes and touch functionality for seamless interaction. By digitizing work instructions and integrating them with the MES system, we help ensure unified management and the ability to adapt to multi-variety production demands.

Real-Time Production Dashboards - Enhancing Decision-Making with Visualization

Manual data collection in traditional manufacturing environments can lead to delayed decision-making and a lack of real-time insights.

Production Dashboards for Real-Time Visualization

Emdoor’s 21.5-inch HD touch-screen production dashboards offer real-time visualization of key performance indicators (KPIs) such as output, yield, and equipment status. These dashboards are integrated with MES systems and present production data in an easily digestible graphical format. The solution supports wall-mounted installations and remote monitoring, using Intel Celeron processors and an IP65-rated design to ensure continuous, stable operation. With real-time production visualization, managers can quickly identify anomalies, optimize resource allocation, and improve workshop collaboration and efficiency.

Mobile Workstations - Flexibility for Agile Manufacturing

Fixed workstation terminals can restrict operational flexibility, leading to delayed responses and inconvenient data collection.

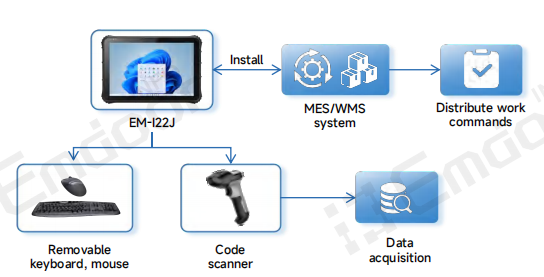

Emdoor's Rugged Mobile Workstations for Flexible Operations

Emdoor rugged mobile workstations are designed to enhance operational agility in industrial environments. The I22J rugged tablet allows for mobile use, seamlessly connecting to MES/ERP systems to enable real-time data collection and updates. Equipped with a removable keyboard and barcode scanner interface, this device supports high-dust and vibration-prone industrial environments, ensuring stable system operation. With mobile workstations, manufacturers can optimize workflow and material flow paths while improving production process visibility and response time.

Conclusion: Enhancing Digital Transformation with Emdoor

Emdoor is committed to helping manufacturers transform their operations through cutting-edge industrial automation solutions. Our rugged industrial computing devices, such as the P10A, P15A, P21A, and I22J, enable real-time monitoring, efficient data management, and seamless integration with MES systems, improving manufacturing efficiency, reducing downtime, and driving operational excellence.

Stay tuned for the next chapter of our smart manufacturing series, where we’ll dive into predictive equipment maintenance and how our solutions can help you reduce unplanned downtime and increase overall equipment effectiveness (OEE).