Smart Manufacturing Solutions: Chapter 1-Transforming Inventory and Warehouse Management

As global industries accelerate toward digital transformation, enterprises are looking for more reliable, intelligent, and efficient ways to optimize operations. Emdoor, a leading provider of rugged terminals and industrial computing solutions, is committed to empowering manufacturers with end-to-end smart manufacturing solutions. This article is the first in our five-part series exploring how rugged devices and intelligent systems reshape the manufacturing value chain, beginning with inventory and warehouse management.

What Is Smart Manufacturing?

Smart manufacturing is an advanced production model that integrates design, production, management, and services with next-generation information technologies such as IoT, cloud computing, big data, and AI. It enables real-time self-perception, intelligent optimization, and precise control across operations. Emdoor’s smart manufacturing solutions are designed for workshop, factory, and supply chain scenarios, helping industries such as semiconductors, electronics, automotive, food & beverage, and textiles achieve digital transformation and operational excellence.

Challenges in Warehouse and Inventory Management

Traditional warehouse systems often suffer from inefficiencies such as high error rates, slow processing, poor visibility, and safety concerns. Manual picking and shelving introduce frequent mistakes, forklift operations lack real-time coordination, cold chain environments degrade device performance, and manual stocktaking causes delays and data inconsistencies. These challenges hinder productivity and prevent enterprises from achieving the fine-grained management required in modern manufacturing.

Emdoor Smart Warehousing Solutions

To address these challenges, Emdoor provides a comprehensive suite of rugged devices and intelligent systems designed to streamline warehouse operations. Our solutions cover five key application scenarios: inbound/outbound operations, product picking and shelving, forklift transport, cold chain warehousing, and intelligent stocktaking. By leveraging rugged handheld terminals, vehicle-mounted PCs, and IoT connectivity, enterprises can significantly reduce errors, improve traceability, and achieve real-time operational visibility.

1. Inbound and Outbound Operations with the H60T

The Emdoor H60T rugged handheld terminal is designed to digitize warehouse workflows. Staff can scan cargo barcodes, with information automatically uploaded to the WMS system for end-to-end visibility. Equipped with a professional-grade 2D scanning engine, GPS for optimal sorting routes, dual 5G SIM, dual-band Wi-Fi, and a hot-swappable battery, the H60T ensures accuracy, efficiency, and continuous operation. The result: faster cargo turnover, reduced labor costs, and complete traceability.

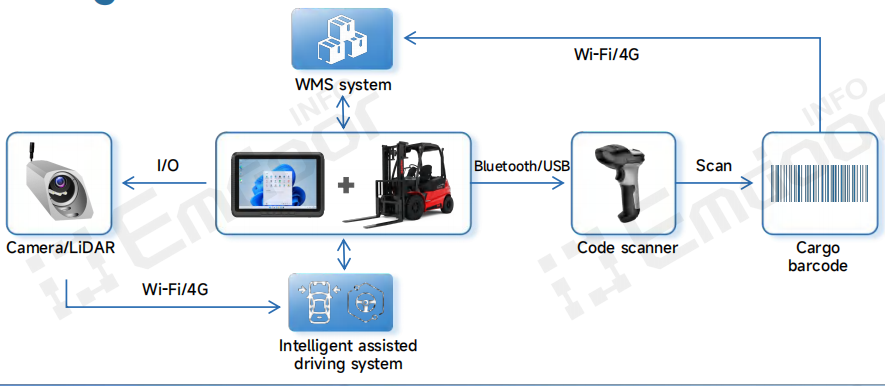

2. Forklift Transport Optimization with the V10J

Forklift operations often face issues such as delayed communication, inefficient routing, and safety risks. The Emdoor V10J vehicle-mounted PC addresses these challenges by integrating directly with WMS and ERP systems. Featuring an Intel N5100 processor, barcode scanner, multiple connectivity options (Wi-Fi, Bluetooth, 4G, GPS), cameras, and LiDAR sensors, the V10J enables digital command reception, real-time cargo handling, and assisted driving. This dramatically improves both safety and operational efficiency in warehouse logistics.

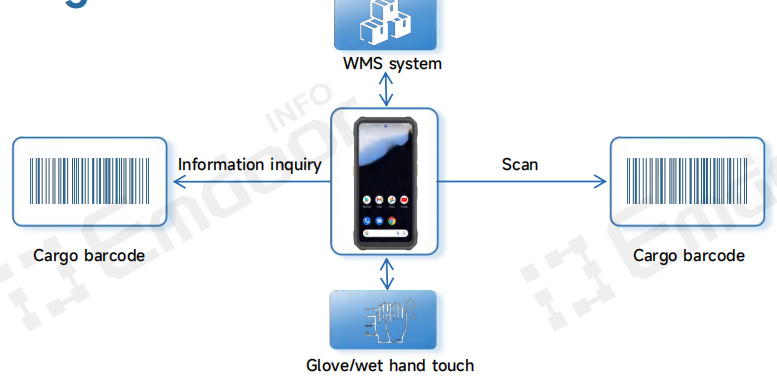

3. Cold Chain Warehousing with the H68T

Cold storage facilities demand equipment that performs reliably below -20°C. The Emdoor H68T rugged handheld terminal meets this requirement with a dedicated 5800mAh low-temperature battery, delivering over 12 hours of continuous operation. With an IP68 waterproof rating, glove-friendly touchscreen, fog-resistant display, and long-range scanning engine, the H68T ensures uninterrupted performance in harsh cold chain environments. Real-time data transfer to WMS systems guarantees accuracy and reliability.

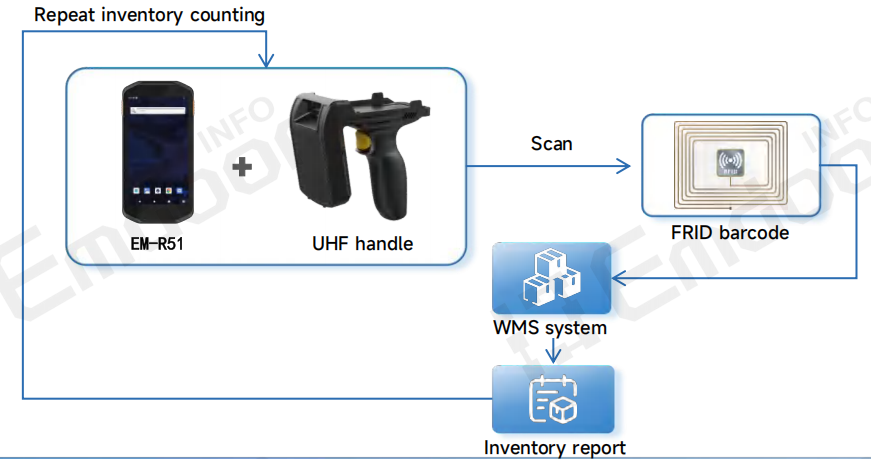

4. Smart Inventory Counting with the R51 + RFID

Manual stocktaking is slow, error-prone, and costly. The Emdoor R51 handheld terminal, when paired with an RFID scanner, enables long-range, batch reading of RFID tags. Supporting dual 5G/Wi-Fi and customizable Kiosk mode, it ensures uninterrupted data upload to WMS systems while preventing employee distraction. With a high-capacity battery for intensive operations, the R51 delivers real-time, accurate, and fully digital inventory management, reducing delays and enhancing competitiveness.

Conclusion: Building the Future of Smart Warehousing

By combining rugged computers, vehicle-mounted PCs, and intelligent connectivity, Emdoor’s smart warehouse solutions eliminate traditional inefficiencies and create safer, smarter, and more connected workflows. As the foundation of smart manufacturing, intelligent warehousing is no longer optional—it is the key to achieving resilience, precision, and growth in the digital era.

This article is the first in our Smart Manufacturing Solutions Series. Stay tuned as we explore how rugged technologies are transforming industrial automation, quality inspection, predictive maintenance, and environmental monitoring in upcoming editions.