The fifth pillar of smart manufacturing is Safety and Environmental Monitoring. This section will focus on three core scenarios: personnel monitoring and management, environmental monitoring, and energy consumption management, along with real-world customer cases. It demonstrates how Emdoor Information helps enterprises achieve safe production, green manufacturing, and efficient energy management through intelligent terminals.

Personnel Monitoring and Management

In traditional production, there are problems such as low personnel efficiency, non-standard operation, and omission of steps, which directly affect product quality and production safety.

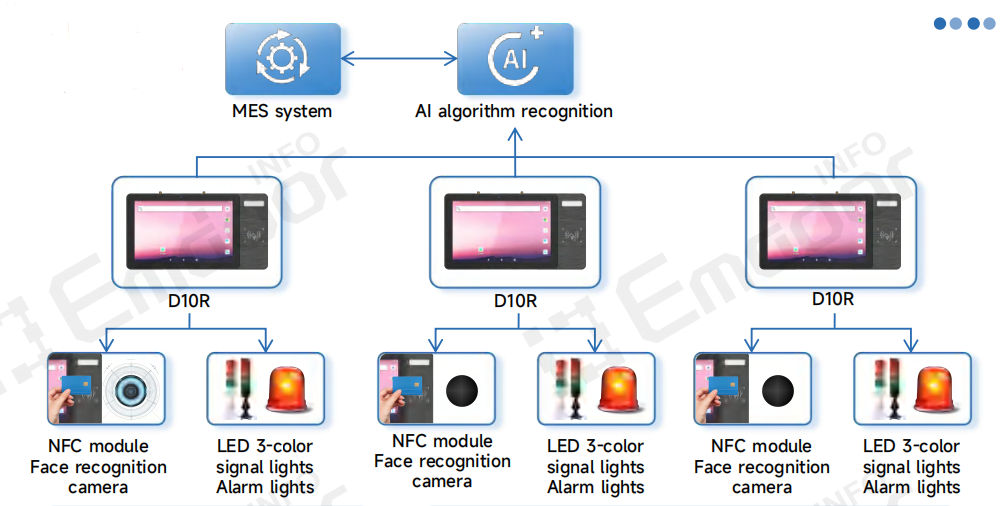

To address these challenges, we launched the Emdoor Information Digital Signage D10R. The digital signage integrates an NFC area to realize employee card swiping sign-in and can also include a facial recognition camera. With AI algorithms and model data, it can monitor employees' behaviors and operational processes in real time to ensure compliance and control of the production process.

The D10R features a 10.1-inch high-brightness display with IP65-rated protection, an integrated NFC module, and a facial recognition camera, with an optional QR code scanning module. The system workflow includes employee card swiping check-in, behavioral recognition, anomaly alerts, and data upload to the MES system. Real-time alerts via LED three-color signal lights and external alarm lights enable managers to intervene promptly when anomalies occur.

Environmental Monitoring

Many enterprises still use traditional equipment for manual recording, which results in inaccurate environmental data, poor control, and data delays. These issues make it difficult to meet the requirements of process control.

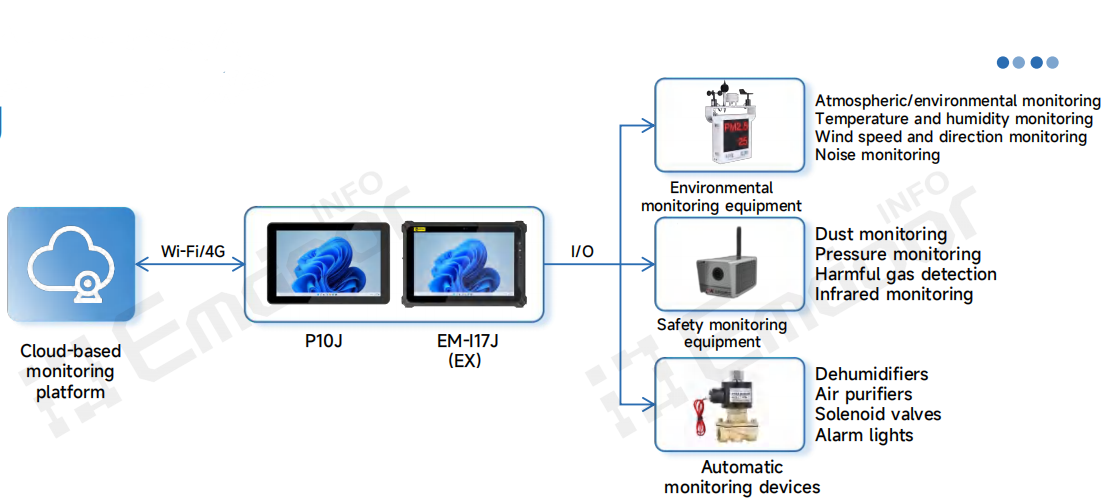

We offer two types of solutions: fixed and mobile, suitable for different monitoring scenarios. The fixed solution adopts the Emdoor Information Industrial Panel PC P10J, connected to the intelligent sensor of the automatic control system. This system monitors and records environmental parameters such as temperature, humidity, and pressure in real time, making adjustments to automatic equipment when necessary.

The mobile solution uses the rugged tablet EM-I17J (EX), which is ATEX certified and ideal for mobile monitoring in hazardous environments.

Energy Consumption Management

The traditional energy consumption management mode of enterprises has many disadvantages. With increasing environmental pressure and stricter regulations, the lack of unified data collection and management has led to difficulties in effectively managing energy consumption.

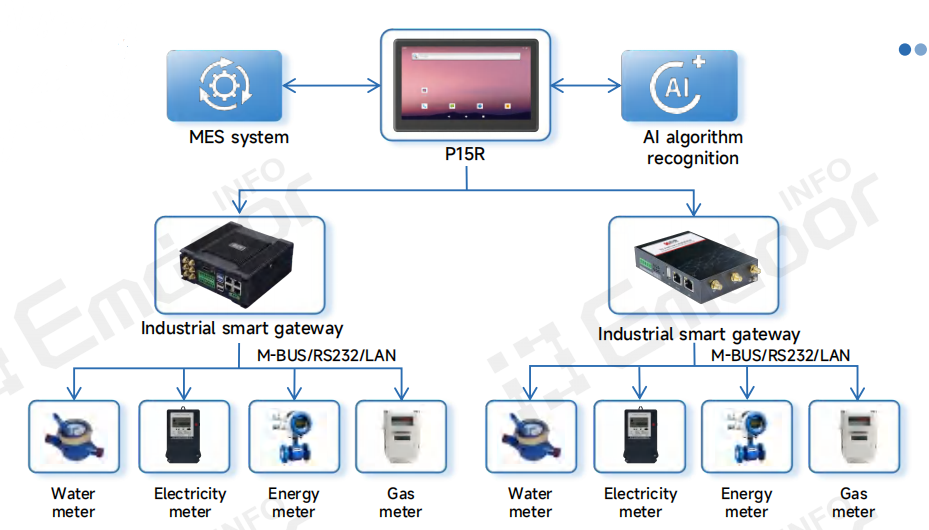

Emdoor Information’s P15R Industrial Panel PC connects to water, electricity, and gas meters via RS232/LAN interfaces, enabling real-time energy consumption data collection and upload to monitoring platforms. Featuring an RK3568 processor with built-in high-performance NPU and 4G/5G expansion capabilities, this fully enclosed design ensures 24/7 stable operation, effectively handling complex industrial environments.

This solution achieves a win-win in both economic benefits and social responsibility, empowering businesses to meet energy efficiency targets and reduce their environmental footprint.