With the increasing market competition, it is of utmost importance for enterprises to improve production efficiency and reduce operating costs. Warehousing and logistics management are now widely used in various industries. However, due to the low level of industry informatization and facility automation, inventory management is chaotic, express package information is scattered, and low efficiency often occurs. Designing and establishing a complete set of warehouse management processes, improving warehouse turnover rate, reducing the occupation of operating funds, and reducing the cost caused by eliminating warehousing are the important parts of improving production efficiency for enterprises.

Emdoor INFO's rugged handheld terminals and tablet pcs instead of traditional manual operations help enterprises easily realize digital and transparent management. Barcode recognition technology collects and inquires on cargo information. Therefore, I divide the whole Warehouse & Logistics management into seven parts, and this article focuses on the second parts. I will share the following parts in the next five blogs every week.

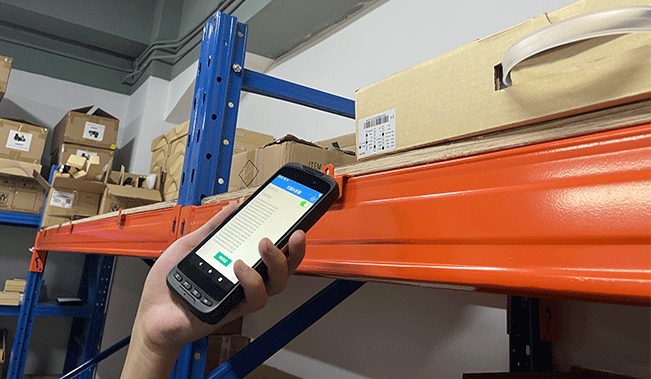

In traditional outbound management, the warehouse outbound operations are finished by workers, which has a large workload, time-consuming, low efficiency, and high error rate. After the delivery is completed, the staff needs to secondly transcribe the records on the paper to the back-end system, which completely relies on manual data update methods. Often due to various uncertain factors, the inventory and accounts cannot be synchronized, and the efficiency of distribution and delivery is low. Finally, the managers are unable to grasp the real usage of the warehouse in time and formulate a reasonable warehousing plan.

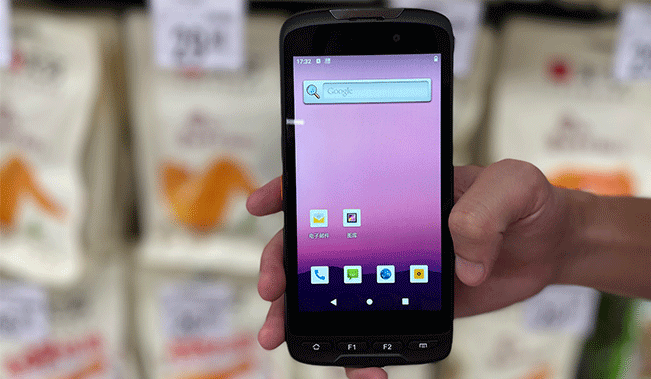

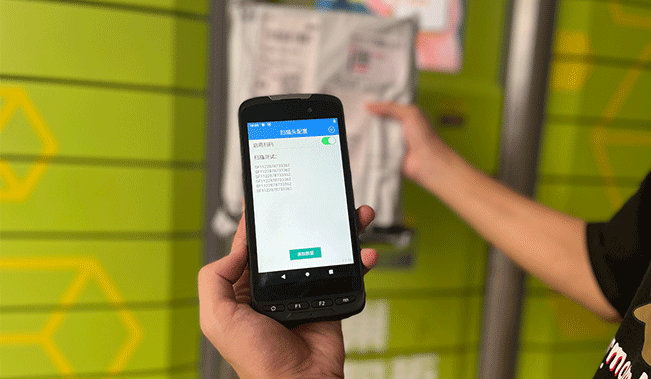

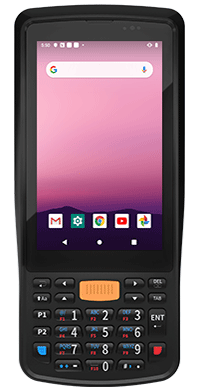

You can use Emdoor INFO's handheld terminal EM-T50, and perform operations such as intelligent verification, statistics, and data reporting on outbound commodities. Operators only need to hold the PDA, receive the outbound information through the wireless network in real-time, use the bar code function to automatically identify and compare the products, and upload statistics to the database system, update inventory information in time, and complete the outbound operation accurately, efficiently and intelligently.

1. The rugged handheld terminal EM-T50 can receive the outbound information in real-time by the wireless network, and automatically check and record the outbound products, without manual copying and comparison, to avoid errors such as multiple outbound and leaked outbound errors caused by human error;

2. The location information is transmitted to the database system in time to ensure that the system accounts are always synchronized with the physical objects;

3. Accurate and real-time inventory dynamics, efficient storage and retrieval efficiency, and accurate and error-free account checking. It has further realized the optimal configuration and management of warehousing goods.

4. The rugged handheld EM-T50 is equipped with an imported scanning head, which can quickly and accurately identify and read barcodes, QR codes, curl codes, pollution codes, fuzzy barcodes, etc. The efficient product identification capabilities greatly improve the work efficiency of operators.

Thank you for your attention on Emdoor Rugged PC!

Please fill the form to let us know your need. We will get in touch with you ASAP.