Thank you for your attention on Emdoor Rugged PC!

Please fill the form to let us know your need. We will get in touch with you ASAP.

Background

With the completion of customers' new precision CNC workshops and the increasing number of CNC equipment, a large number of paper documents will be produced during the production execution process. As a result, a lot of manpower and material resources are wasted in the management of paper documents, and the continuous increase of on-site workload has affected the production efficiency of enterprises.

Challenge

1. Drawings, technical data, and process information are managed by manual methods such as traditional paper printing, distribution, recycling, and version changes, which seriously affect the improvement of enterprise management efficiency. In these manual operations, there are problems such as time lag and error proneness;

2. A large number of paper documents need to consume a lot of manpower and resources to manage. At the same time, there are some production problems such as poor traceability, information islands, and prone to loss and damage of documents;

3. The operation documents obtained from the experience of the field operators are kept in the hands of the operators, and they cannot be collected and archived in a timely manner, which is difficult to share and track.

Introduction

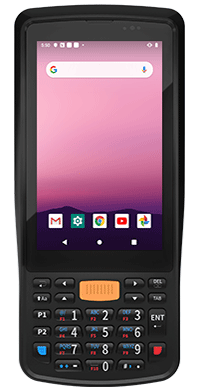

In response to the customer's problems, Emdoor, a reliable rugged tablet OEM, recommends a rugged handheld PC EM-I62H with an MES system, which has functions such as barcode scanning identification, electronic drawing file browsing, process file browsing, and authority management. The rugged handheld android tablet can be responsible for data collection and process control of key elements (human, machine, material, method, environment, measurement) in the factory production process, and solves the tracking and management of the production task execution process. For this rugged handheld PC, the processing process has been effectively controlled, and the refined management level has been effectively improved. The production files are uniformly managed at the production site, and they are shared and stored centrally. They have traceability, improve work efficiency, and are economical and environmentally friendly. They ensure the convenience and security of information flow and realize paperless management in factories.

Realize the issuance, recall, editing, check-in, and check-out of production data files, ensure the accuracy and uniqueness of the files, and improve product quality;

Data collection and process management for the processes of incoming materials, production, shipping quality, and returns;

On-site personnel can scan the barcode to trigger the system, automatically locate and find the corresponding guidance production documents, and quickly push them to the on-site terminal of the station to guide;

Achieve process version synchronization;

Monitor processing information, quality control, equipment operation status, etc., can timely detect various production problems during production execution and respond quickly;

It can quickly trace back the processing information and quality control information of the product, which greatly reduces the time for searching historical information.

Thank you for your attention on Emdoor Rugged PC!

Please fill the form to let us know your need. We will get in touch with you ASAP.